Roll Forming

Filter by Process Zone:

Roll-Kraft Welcomes New Engineer at Ohio Headquarters

Tony Romito brings considerable experience in the design and optimization of roll form tooling for new and existing fixturing.

Roll-Kraft Expands Sales Team

They hire Sean Larkin as a technical performance specialist.

Roll-Kraft Adds CFO

Jacqueline Kato is their new chief financial officer.

Roll-Kraft Names New VP

Chaz Rau is their new vice president of precision process performance.

Roll-Kraft Installs New Parts Washer

This new unit should increase their efficiency in preparing incoming rolls for regrind.

JPW Launches Online University for Metalworking

JPW IQ uses e-learning to connect their buying groups, distributors, and sales reps with their brands.

Roll-Kraft Names New CFO

Ken Fruscella is their new chief financial officer.

Racine Metal-Fab Celebrates Milestone

They are celebrating 50 years of success in the sheet metal fabrication business.

Roll-Kraft Names Director of Operations

Kevin Gehrisch now oversees production, sales and strategic planning.

Chicago Roll Company Installs New Turning Center

This will allow them to produce rolls with a maximum diameter of 35 in and maximum length of 39.4 in.

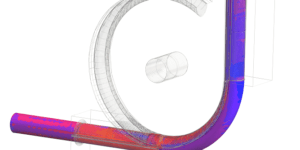

Simulation of Tube Embossing and Bending for Roll Formers

Roll forming procedures, pre- and post-processing steps can be optimally calculated to improve the forming process as a whole using COPRA FEA RF software from data M, which visualizes and verifies the production process within a virtual environment to prevent deviations during production.

Don’t Play with Fire: Preventative Maintenance on Roll Formers Saves Money and Time

If you run your roll former 24/7 without maintenance, you’re playing with fire. Every maintenance program is a little bit different, but this general outline is useful for any metal roll forming machine. It includes some points of emphasis to consider, and some things that may get overlooked.