Robotics / Automation

Filter by Process Zone:

Industrial Magnetics, Inc. Welcomes Regional Manager

Navy veteran Aaron Evans is IMI’s new Western U.S regional manager.

Programming a Robot Doesn’t Have to be a Dark Art

As production goals change in a post-pandemic world, more manufacturers are using robots to deal with labor shortages and high-mix, low-volume (HMLV) orders. Easy-to-use tools for novice operators are enabling faster implementation on factory floors.

World’s First Robot With Process-Optimized Motion Modes

In addition to providing the longest reach in the high-payload category and featuring a slimmer profile, KUKA’s updated KR Quantec robot offers three software plug-ins to maximize performance, path, and cycle times.

So Simple Even a Beginner Can Use It: Instant Feedback Minimizes Programming Errors

By automatically calculating the user’s orientation relative to the robot, Yaskawa Motoman’s tablet-based Smart Pendant eliminates the need to use conventional X, Y, Z coordinates. No hard copy manuals required, either.

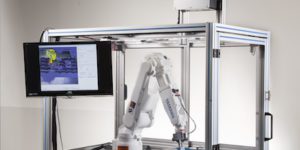

Single-Step Bin-Picking Solution Greatly Lowers Cycle Times

Yaskawa Motoman’s turnkey MotoSight 3D BinPick handling system uses just one camera to identify randomly placed parts. Three camera models are available to cover a range of part and bin sizes.

Autonomous Transporter Forges the Most-Efficient Path Through a Job Shop

The strongest and most recent addition to the LD Series of autonomous mobile robots from Omron Automation Americas moves 550 pounds (250 kg) while enabling manufacturers to control a fleet of 100 robots using a single system.

7-Axis Cobot With Fast Teaching and Simple Controls

Armed with torque sensors in all 7 axes that detect and immediately react to contact with a human coworker, KUKA’s LBR iiwa eliminates the need for safety fences for true human-robot collaboration (HRC).

Palletizer’s Robot Arm Simplifies Complex Processes

With a compact design that consumes 40% less space, Flexlink’s RI20 can be relocated in a few hours and used in multiple lines in a single day. Meanwhile, operators and robots can safely coexist on the production floor.

Fast-Access Storage Saves the Day for Metal Products Specialist

The increased demand in the cut-to-size sheet segment was making storage space tight at AMCO Metal Service GmbH’s premises in Germany – then they discovered KASTO’s Unigrip 3.0 storage system that increased productivity and fast access to materials and finished parts.

Will the Real Collaborative Robot (aka Cobot) Please Stand Up?

A robotic system is ‘collaborative’ only if all elements – robot, tooling, workpiece, and work area – meet international safety standards. Depending on application, you may be able to turn a standard industrial robot into a cobot and comply.

KUKA 2020 Product Introductions Include…

The German industrial robot manufacturer and automation solutions provider plans to introduce a robot with the largest work envelope in the medium-payload-class to the North American market and an online service portal during the International Manufacturing Technology Show in September.

Next-Generation CSD Series Twin-Spindle Lathe

An upgrade to the CSD-300 twin-spindle lathe, the front-facing CSD-300II from Fuji Machine America is more robust and loaded with new-or-improved features for faster and easier operation than its predecessor.