Robotics / Automation

Filter by Process Zone:

Wireless Communications Solution Lowers Material Handling Time and Errors

ROEQ’s replaces Wi-Fi-dependent third-party setups with a sensor-based system that automatically lifts loads delivered by an autonomous mobile robot (AMR) to the proper height for delivery to a stationary conveyor.

Fully Automated Material Handling with ‘One System Fits All’ Module and Cobot-Armed Gates

The QM180 top module from Nord Modules increases the utility of autonomous mobile robots (AMRs) by connecting with a cobot-powered gate to create the first fully autonomous material-handling system. It also handles half pallets, plastic boxes, carton boxes, and carts without changing top modules.

AGV/AMRs Make Moving Loads a No-Brainer

Material-handling solutions developer Kivnon expands its mobile vehicles portfolio with two autonomous mobile robot (AMR) forklifts and an automated guided vehicle (AGV) lifting platform that rotates.

Tow Tractor Moves 11,000 Pounds Automatically or Manually via a Driver

Jungheinrich’s dual-mode EZS 350a NA automated guided vehicle (AGV) provides all the benefits of an electric truck with a laser-based navigation platform that requires no floor work.

Small-Payload Cobot Provides Industrial Speed and Cobot Safety

Comau adds safety features to the Racer-5 industrial robot to come up with the dual-mode Racer-5 Cobot: a fast automation solution for supporting multiple manufacturing processes that doesn’t sacrifice precision or employee health.

Award-Winning Design in High-Speed, 4-Axis Robots

Stäubli has set new benchmarks in dynamics, precision and cleanroom with its 4-axis line of Selective Compliance Assembly Robot Arms (SCARA) for highly sensitive environments. Judges of the 2021 Red Dot Design competition recognized its unique cylindrical working area when they gave it the “Product Design” award.

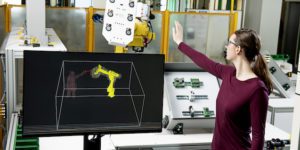

Award-Winning Safeguarding Solution for Industrial Robots Lowers Collaboration Costs

Veo Robotics’ FreeMove sensors-and-software system uses advanced computer vision and 3D sensing to safely turn a high-speed, heavy-load industrial robot arm into a collaborative robot (cobot) that’s faster – and thus more productive – than traditional cobots.

High-Speed Cobot Ensures Safety Without Compromising Productivity

Designed to support intermittent interaction between human and industrial robot, ABB Robotics’ 1100 Swifti CRB (for “collaborative robot”) automatically slows, stops, and restarts depending on an employee’s presence in preprogrammed safety zones.

World’s Most Powerful Vacuum Gripper Cost-Effectively Lifts Heavy Loads

Capable of lifting 44 pounds (20 kg), OnRobot’s electrically powered VGP20 vacuum gripper performs the same heavy-duty tasks as a pneumatic gripper for a fraction of the cost and complexity. Compatible with all major robot brands.

Cleanroom-Ready Gripper for Demanding Applications

OnRobot’s IP67-certified, collaborative 2FG7 parallel gripper is the latest addition to OnRobot’s range of no-fuss, all-electric gripper products. Deployed within minutes, it’s designed to handle demanding payloads, even where space is tight.

Three Cobots with Built-In Vision Systems

Delivering payloads ranging from 9 to 31 pounds and reach up to 4.25 feet, the TM5, TM12, and TM14 cobots from Techman Robot can “see” and automatically reposition objects using a smart user interface.

All-in-One Kits for Quality Assurance Using Universal Robots’ UR3e Cobot

Designed for Universal Robots’ UR3e cobot arm, the Q-Span Workstation from New Scale Robotics comes with everything necessary to automate small-part measurement inspection. You can improve gage R&R and boost capacity without adding headcount.