Robotics / Automation

Filter by Process Zone:

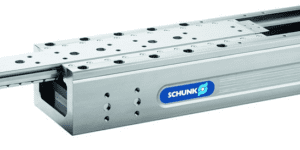

A New Benchmark for Linear Modules

Ideal for clean environments, such as assembly and testing systems, the ELP electric linear module from SCHUNK has end positions that can be mechanically adjusted with a screw and the speed of extension and retraction is adjusted using rotary switches on the side of the unit. Speed can be automatically adjusted depending on extension weight.

Yaskawa Motoman Names New VP of Sales & Marketing

Doug Burnside is their new vice president of North American sales and marketing.

Connecting Multi-Purpose Machine Tools with Robotic Loading Centers

To effectively process large parts, Selway Machine Tool connects a compact Eurotech Spinner TTC300 dual spindle/dual turret multi-process turning center to a Trinity TCL-10 loading center with a Fanuc M10iA robot, and a compact Matsuura MX-330 5-axis vertical machining center to a Trinity MCL-35f loading center with a with a Fanuc M20iA-35M robot.

New Paths for Mobile Robotics

As shops face the pressures of mass customization, changing requirements and labor shortages, innovative autonomous industrial mobile manipulators are being introduced to relocate the robot arm throughout the facility to perform different tasks, such as part replenishment, machine loading or fulfillment, and more.

Yaskawa Mexico Names New General Manager

Jorge Cosio now leads their strategic direction, sales growth in Mexico, and the operation of their three facilities.

German Delegates Tour Messer Cutting Systems

The dignitaries from Hessen were given short presentations, walking tours through Messer and Castolin Eutectics, and live plasma cutting machine demonstrations.

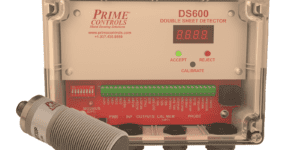

Prime Controls President is Honored

Beth Graves is named one of the winners of the 2017 Forty Under 40 award.

Double Metal Sheet Detection for Metal Stamping

Ideal for automation applications in robotics, automated de-stackers, sheet feeders and in-fixture (poke-a-yoke) where sensing from only one side is possible, the DS600 Double Sheet Detection Control from Prime Controls detects metal thickness and prevents double sheets or improper thicknesses from entering machines.

The Culture Shock of Safety First

They might come as a shock to some accountants, but the productivity gains, cost savings and other returns on investing in a safety-first culture are very real to the people who spend most of their days on the shop floor. After identifying safety trouble spots and investing in automated equipment that provides as inherently safe a workplace as possible, we have reduced workers’ compensation claims to near zero.

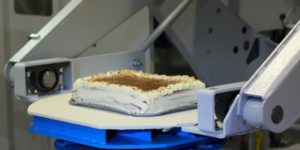

Automated Turret Punch Press Loading

Ideal for handling full-size blank sheets and finished parts, FS Tower Series cell stocker systems from Murata Machinery can double the production of a stand-alone machine and provide lights out, unattended operation during breaks, shift changes, lunch and after hours, as well as more consistent production to improve job estimates and costs.

Flexible Handling and Storage of Sheet Metal Inventory

The BASIC Tower Sheet Metal 4.0 system from Remmert allows shops to keep an economically sensible stock of sheet metal inventory while maintaining flexible handling of the material.

Flexible Automated Material Handling for Unmanned Production

For CNC machine tools, the Flexible Pallet Container pallet handling system from Fastems enables operators to set up new pallets while parts on other pallets are being completed, eliminating the need to stop machining to change setups.