Resistance Welders

Filter by Process Zone:

Resistance Welders for Any Lot and Part Size

Financing, lease, rental, and recondition-to-new programs are available for all Seedorff ACME rocker arm, pedestal, bench, press-type, seam, butt-and-tee and multispot resistance welders. Automation options available.

Ultrasonic Metal Spot Welder Delivers Repeatable, High-Quality Results

The actuator’s dual linear bearings and a digital load cell enable Emerson Industrial Automation’s Branson GMX-20MA ultrasonic spot welder to deliver consistent quality from weld to weld by maintaining energy levels.

A Different Type of Bond – Hold the Filler Metal, Please

Solid state and resistance welding use pressure and/or electric current to fuse dissimilar metals, nonferrous metals, and composites without generating defects, like gas porosity and hot cracking, seen in fusion welding. Think things like bus bars and switches in automotive electric systems and appliances and nuts and fittings on various parts.

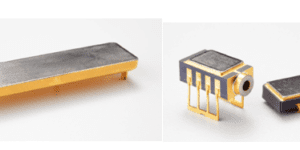

Hermetic Seam Sealing Enables Reliable Welds and Protects Electronic Devices from Harsh Environments

A primer on the two processes – parallel gap resistance seam welding or opposed electrode projection resistance welding – you can use to win customers in the highly demanding aerospace, industrial 5G commercial communications, medical device, and military electronic industries.

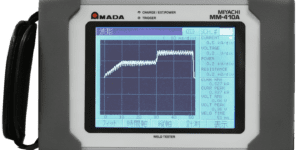

Dual-Purpose Handheld Resistance Weld Checker

Amada Miyachi America’s compact MM-410A supports process development and production applications for resistance welding technologies including AC, DC inverter, AC inverter, transistor, and capacitive discharge. Data storage is available using an onboard flash drive.

New Engineer Joins Dengensha

Shandell Monge is their new sales engineer.

Dengensha America Opens New Office

This sales and service site in Duluth, GA, will focus on southern automaker expansion.

Ultralight Magnesium Alloys for Superior Welding

An affordable, high performance and sustainable alternative to aluminum, steel and titanium, ultralight ALLITE Super Magnesium alloys are specifically designed for superior welding, forging, strength and stability.

Advanced Capacitor Discharge Welders

LinearWave Capacitor Discharge Welders from Dengensha America are ideal for welding high strength steel, aluminum, and large projection and ring projection parts.

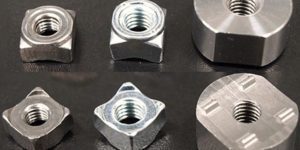

A Breakthrough in Capacitor Discharge Welding

For CD welding used in gear manufacturing or when joining nuts and bolts with different material and wall thickness combinations, the Multi-Capacitor Source system from Taylor-Winfield can specifically influence the course of the welding current and tailor process control to the joining task.

Next Steps in Capacitive Discharge Welding

The tightly restricted limits of Capacitive Discharge welding can now be expanded with the Multi-Capacitor Source system, which can customize the process control for a specific joining task.

Weld Systems Integrators Adds New Lab Capabilities

This investment strengthens their projection welding capabilities of fasteners to various alloys and the latest Gen III materials.