Punches and Dies

Filter by Process Zone:

Tooling Tech Group Installs New Stamping Press

This new 2,750 ton Eagle press will expand their capabilities into the transfer die business.

Why Invest in a Tapping Tool?

Though there are less expensive methods for adding threads to sheet metal parts, in-punch tapping is far and away the fastest, most accurate way to produce threads. Ultimately, the decision comes down to the thread type, specification and how many tapped holes are needed.

Guided Pierce Cylinders for Appliance Manufacturing

These hydraulic cylinders from Coldwater Machine feature an internally self-lubricated, guided rod inside a steel cylinder body that provides stable, non-rotating performance with the ability to reach hydraulic pressure of up to 3,000 psi.

How to Correctly Calculate an Unfolded Part

Understanding the relationship between the V-opening, radius, bending allowance, and K factor can help you to properly calculate an unfolded part for more accurate bending on a press brake.

Strong Supplier Partnerships are About Much More Than Price

A healthy relationship goes beyond a vendor’s ability to consistently deliver performance, reliability, quality and customer service at a competitive price. The key is putting the right people in place to foster mutual trust and flexibility. As our industry continues to evolve, so too must our relationships with our customers and suppliers.

New Advances in Die Design Software

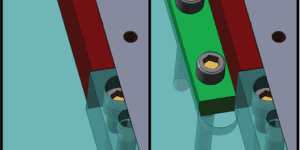

The 2018 version of SolidWorks-based Logopress3 die design software from Accurate Die Design Software can show the actual slugs underneath the punches that will be falling though the die openings.

Magnetic Safety System for Easier, Safer Front Loading of Punches on Press Brakes

The Maglock magnetic safety system on American Precision Style press brake tooling from Mate Precision Tooling attaches and seats the punch to the holder with no separation between the surfaces. Punches install facing forward or backward with magnetic power and simple tangs for front loading.

Crowning Deflection Control System for Press Brakes

The Express Crowning system from Wilson Tool helps control deflection or “the canoe effect” in press brake applications over 4 ft long with quick, repeatable crowning that is precisely adjusted by a basic hand crank and digital readout or an electric motor driven by the CNC machine control.

Press System with In-Die Laser Welding Eliminates Time-Intensive Labor

The laser welding, parts assembly and cut-off operations inside the pneumatic stamping press system with in-die laser welding capability from Airam eliminate time-intensive labor, improve repeatability and reduce material handling without sacrificing production speed.

Why Invest in Custom Press Brake Tooling?

Are you facing a complex bending challenge, a unique part design or press brake productivity dilemma? If so, it’s time to consider investing in custom press brake tooling now that can pay off in spades down the road through increased bending performance and improved part quality.

Wilson Tool Launches New Spanish Website

Easier navigation, intuitive functionality and in-depth resources combine with enhanced search capabilities for easy tooling selection available locally.

Wila USA Names New President

Chris Morse now heads up their North American business.