Punches and Dies

Filter by Process Zone:

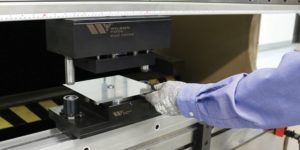

Need More Punching Capacity? Turn Your Press Brake Into a Punch Press

Does limited punching capacity and outsourcing lead times cause production delays in your shop? Here is a simple, affordable and effective system that can expand the capabilities of your press brakes, help streamline operations and eliminate the need for outsourcing or purchasing new equipment.

Tooling that Increases Uptime in Metal Fabrication Operations

These punching, bending and laser fabrication tools from Mate can reduce setup times, shorten process times, improve safety and increase shop profitability in fabrication operations.

Majestic Industries Expands Into Transfer Dies

Their capabilities now include transfer die try-out and production of large tools under one ram.

Increase Tool Life with Preventive Maintenance

Deliberately pull a die out of the stamping press for tool maintenance even though it is still producing perfect parts? That’s right. Don’t wait for that next emergency to shut everything down to put out fires. You can actually reduce downtime by regularly scheduling preventive tool maintenance that provides longer tool life, fewer scrapped parts and improved productivity.

TTG Hires Corporate Sales Executive

Kelly Connors will help solve customer tooling problems and foster long-term relationships.

May the Press Force Be with You: Tips and Tricks for High Tonnage Bending

Bending thick plates requires more attention to certain details than lighter bending jobs. Here are some ways to get all your ducks in a row before you bend the first part, so that your job will go more smoothly and translate into more profitable production.

Choosing the Right Shear for Your Application

Five different types of shear grinds for punch press tooling can reduce the amount of punching force required, increase tool life when side loading is not a concern, and minimize the amount of wear on the machine. Here are some tips on how to choose the correct option for a specific application.

Metal Stamping Industry Projections for 2019

The metal stamping business is still strong, the labor pool is depleted, pressrooms are busier today than yesterday, and growth should continue in the year ahead. But be prepared for the unexpected and the transition into the new economy of metalworking.

Majestic Industries Achieves IATF Certification

They are certified for Automotive Quality Management System IATF 16949 for producing metal stampings and stamping dies.

Understanding Press Brake Tooling Tonnage Ratings and Calculations

There are various ways to measure tonnage capacity in press brake tooling, so it’s important to look beyond the tooling catalog when doing comparisons to really understand the numbers being displayed. Understanding the units of measure most commonly used to measure tonnage capacity is a crucial first step.

Industry 4.0 Press Brake Tool Management

The Smart Tooling App from Wila includes a smartphone app for Android and iOS that allows users access to their press brake tool data anytime, anywhere for major time savings, error-free tool data entry and simplified stock management.

Faster Turret Press and Press Brake Setups, Improved Slitting of Thick Materials, and Fiber and CO2 Laser Cutting

Mate Precision offers QCT Metric quick change tool-less tooling, the Versadie HD clamp clearing system that uses unique design features to improve slitting thick materials, and Laser Accessories to help shops improve their fabricating efficiency.