Punches and Dies

Filter by Process Zone:

New Director of Sales at Wilson Tool

Ron Palick takes over responsibility for developing sales in North America.

Dayton Lamina Names New VP

Bill Mills is the new vice president of U.S. sales and marketing operations.

Unitized Punch Tooling Applications

Multicyl combines the standard Multicyl MC series, the HZ frame, and the HZ unit from Unipunch to punch angles, tube edges, and hard to reach extrusions.

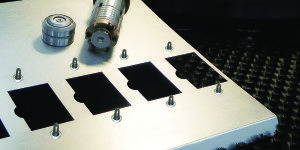

Prevent Slugs from Pulling onto Stamping Die Surface

The Rev 3 Slug Retention Machine from DTC eliminates the need to remove the die from the press, disassemble it and return it to the press after reworking it.

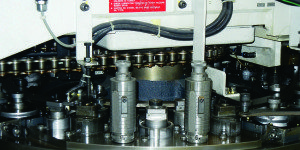

Clever Turret Press Tooling Produces More Parts In Less Time

Tooling changeover is a priority for this sheet metal job shop, which achieves quick setups, extra durability and increased uptime by using advanced tooling that makes its turret presses “operate like new.”

Form Mates with Function in Turret Punch Tooling

Forming operations take center stage on the turret punch press through some new tooling innovations from Mate Precision Tooling.

Wilson Venture Group Seeks To Acquire Promising Small- To Mid-Size Businesses

The family-owned firm is focused on the acquisition of similar family-owned businesses in need of an exit strategy as well as entrepreneurs looking to sell their product or technology.

Compact Power Unit is Ideal for Small and Midsize Power Press Operations

This new electrically driven high-pressure hydraulic power unit from Hilma Div. of Carr Lane Roemheld is ideal for small and midsize die clamping and lifting systems.

Optimizing Punch-To-Die Clearance

This 6-page, full-color brochure available from Dayton Progress discusses how the 5 percent per side clearance is insufficient for today’s high-strength steels, and walks readers through how to select the proper clearance based on material, thickness, tensile strength, and the requirements of the specific job.

Flexible, Low-Cost Tooling Generates Less Scrap

The fourslide process is capable of cutting typical tooling costs to as little as $3,000, halving tooling lead times, and eliminating after-production adjustment to meet specifications with its unique integration of stamping and forming operations.

Punches and Dies

Punches are simple tools that are forced by a punch press through a workpiece, commonly sheet metal, to create quick, precise holes by shearing. Punches are typically made of carbides or tool steel. Most presses are operated mechanically, but simple…

Dayton Progress Transfers Blank Production to Vietnam

Over the next several years, the MISUMI Vietnam blank factories will expand and adopt the Dayton Progress blank-making process, after which most manufacture of Dayton blanks will transfer from Ohio to the MISUMI plant in Vietnam.