Press Brakes, Panel Benders

Filter by Process Zone:

Bystronic Appoints New Regional Manager

Victor Stepien now manages sales in Iowa, Minnesota, northwest Missouri, Nebraska, North Dakota, South Dakota and Wisconsin.

No Guesswork Involved

With automated tool changing, bend simulation software with 3D part views, intelligent angle measuring systems and other features, here are some new press brakes that can efficiently bend small batches of high-mix parts, including difficult profiles, with high precision at fast speeds.

Precision Bending with Automated Setup for High Productivity

Equipped with a ToolMaster for automatic tool changes in seconds, the extremely quiet TruBend Series 5000 from TRUMPF combines high axis speeds and acceleration rates with innovative operating aids for precise angles with unparalleled productivity.

Hybrid Press Brake Reduces the Cost of Forming Difficult Part Shapes

This quiet running 150 ton hybrid press brake from Cincinnati Incorporated uses bend simulation software with 3D part views, interlocked frame members, programmable ram tilt and an exclusive six-axis linear motor backgage to provide the productivity and versatility needed for demanding fabrication jobs.

Automatic Tool Changing Press Brake with Extended Tooling Capacity

To efficiently bend small batch, high-mix parts, including complex layouts, with high accuracy in minimal changeover time, the versatile ToolCell XT automatic tool changing press brake from LVD Strippit holds 50 percent more tooling to handle varying material types, organize tooling by material type, and easily switch between stainless steel and mild steel applications.

Bystronic Appoints West Coast Regional Manager

Richard Chesnut handles sales and support throughout nine Western states.

Ultrafast Automated Bending Cell

With an average cycle time of four seconds per bend, the robotic TruBend Cell 7000 from TRUMPF delivers automated bending of small parts twice as fast as conventional bending cells.

Robotic Electric Press Brake Cell

For fully automated bending of small to medium-sized parts in varying batch sizes, at bending speeds up to 1 in/sec, the Dyna-Cell robotic bending cell from LVD Strippit integrates a high-speed five-axis electric press brake with a robot for unmanned operation for up to eight hours.

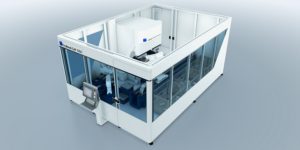

Robotic Mobile Bending Cell

The automated Mobile Bending Cell from Bystronic can process large lots, or bend small lots or individual parts manually when necessary. Just plug in and start bending.

MC Machinery Hires New Regional Sales Manager

Jeff Grim now oversees sales and service within the Southeast region and Indiana.

A Look Ahead

As the metal fabrication business remains strong, watch for more shops to adopt digitization, the principles of Industry 4.0 and integrated process flow as they move toward smaller batch sizes, shorter lead times, high-mix parts to compete – and to address the lack of skilled labor.

May the Press Force Be with You: Tips and Tricks for High Tonnage Bending

Bending thick plates requires more attention to certain details than lighter bending jobs. Here are some ways to get all your ducks in a row before you bend the first part, so that your job will go more smoothly and translate into more profitable production.