Press Brakes, Panel Benders

Filter by Process Zone:

Robotic Bending Cell Available with In-Process Adaptive System

LVD Strippit’s Dyna-Cell with Easy-Form Laser in-process adaptive bending system and programming wizard ensure the desired angle from the first bending operation. Together, the features facilitate automated bending at speeds up to 1 inch (25 mm) per second.

Compact, Affordable, Easy-To-Operate Press Brake

With functions such as choice of tool clamp and back gauge systems and a closed O-frame design that provides space for applications along the entire bending length, the Xpress press brake from Bystronic provides an impressive price-to-performance ratio.

Paul LeTang to Retire from Bystronic

Nicknamed “Dr. Bender,” the press brake product manager begins his next chapter starting March 2.

Bystronic Canada Appoints Direct Sales Engineer

Sylvain Robidoux will support their Western region of Québec province.

Cincinnati Inc. Partners with Hendrick Motorsports

They become an official sponsor through a landmark ten-year agreement.

Cutting-Edge Fabricating Technology

Innovative laser cutting systems, precision bending equipment and other fabricating machinery from TRUMPF introduce new machine features and automation to help shops gain a competitive advantage.

Unmanned Bending System for Small, Medium and Large Batch Sizes

The compact Dyna-Cell robotic bending cell from LVD Strippit automates the bending of small to medium-sized parts in varying batch sizes at bending speeds up to 1 in per second.

Bystronic Names New Sales Representative

John Fresonke now handles direct sales in northern Minnesota and North Dakota.

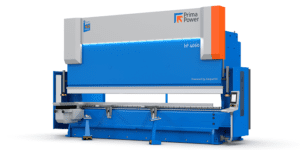

Prima Power Partners with Gasparini

Gasparini is supplying them with medium- and large-format press brakes.

Montage Partners Acquires METALfx

The existing management team of METALfx remains and also owns a meaningful equity stake in the business.

More Than One Way to Skin a Part: Where Fabrication and Machining Overlap

Don’t take the “hard limits” between machining and fabrication for granted. Their areas of overlap offer tremendous potential for savings. If you manufacture parts using both processes, take a second look at some of them to evaluate whether they could be produced more economically with a little sheet metal know-how and some outside-the-box thinking.

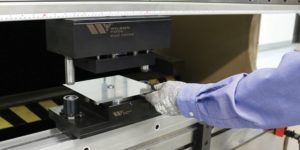

Need More Punching Capacity? Turn Your Press Brake Into a Punch Press

Does limited punching capacity and outsourcing lead times cause production delays in your shop? Here is a simple, affordable and effective system that can expand the capabilities of your press brakes, help streamline operations and eliminate the need for outsourcing or purchasing new equipment.