Plasma Cutting Systems

Filter by Process Zone:

Richards Sheet Metal Celebrates 85th Anniversary with Expansion

Richards Sheet Metal will increase their capacity from approximately 70,000 sq ft to 90,000 sq ft with the expansion.

ESAB Sponsors University of Toronto Baja Team in SAE Design Competition

ESAB will support the University of Toronto Baja Team with the donation of welding equipment, consumables and personal protection accessories as they compete to design and build a rugged off-road vehicle.

The Umbilical Cord of CNC Plasma Tables

The igus 240 series Energy Chain is central to making plasma tables from Arclight function as they should by effectively guiding and protecting machine cables for overall optimal system performance.

Dedicated Commercial Marine Division Established by AT&F

AT&F has opened a location in Charleston, SC which will specialize in commercial marine industry.

Plasma Cutting Systems

This technology forces oxygen, nitrogen, argon, or even shop air through a small nozzle orifice inside a torch to create a high pressured gas flow, then introduces an electric arc started from an external power supply to generate an extremely high…

ESAB Wins Award for Sales and Customer Service, Launches New Blog

The manufacturer of welding equipment was recognized as the “Sales Turnaround of the Year” from more than 1,200 entries from organizations in various industries around the globe.

In the Market for a CNC Plasma Cutting Machine?

Technology can make it difficult to choose the proper system to best fit your current application and also meet your future needs. Here are some important considerations that will help you make the correct selections for your application.

What You Must Know About Piercing Thicker Plate with Plasma

The ability to pierce metal plate is a necessity for many fabricators and steel processing centers. This back-to-basics tutorial explains why using plasma, rather than oxyfuel, is most desirable as it means faster piercing times, faster cut speeds, and a cleaner finished product that translates into higher productivity and profitability.

PLASMA CUTTING: VERSATILE FOR BOTH MANUAL AND MECHANIZED CUTTING APPLICATIONS

The cut quality, consumable life and reliability of the plasma cutters used in the past is just that – a memory of the past! Let’s evaluate the different categories of new plasma cutting systems to show how they can benefit those fabricators of steel parts that have traditionally used traditionally oxy-fuel cutting.

Torch Height Control for Automated Plasma Cutting Applications

Here’s why accurate control of the torch to work distance during all phases and types of plasma cutting operations can be the key to dramatic improvements in cut quality, consumable life, as well as productivity and throughput of the cutting machine.

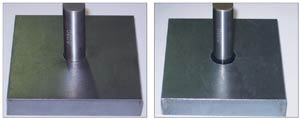

NEW PLASMA CUTTING TECHNOLOGY TAKES CARE OF THE ‘HOLE’ ISSUE

Users of mechanized plasma cutting for plate in the gauge to 1 in thick range can now benefit from a major technological breakthrough. Improved plasma bolt hole cutting can now produce holes that rival drilled holes and plate laser cut holes — at the speed and operating cost of plasma!