Part Marking Equipment

Filter by Process Zone:

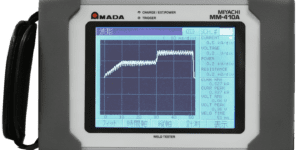

Dual-Purpose Handheld Resistance Weld Checker

Amada Miyachi America’s compact MM-410A supports process development and production applications for resistance welding technologies including AC, DC inverter, AC inverter, transistor, and capacitive discharge. Data storage is available using an onboard flash drive.

The Growing Importance of Direct Part Marking

Traditionally used for fast, error-free traceability of parts in aerospace, medical, automotive and electronics applications, imprinting information directly on parts is ideal for service or recall and assistance in liability and warranty resolution – and it will be needed everywhere as automation and robotics sweep across shop floor operations in Industry 4.0.

Mounted CO2 Laser Lenses Field Replacements for Marking Systems

Drop-in field replacement CO2 laser lenses from Laser Research Optics can reduce downtime, provide < 0.2 percent total absorption values and are coated to match specific phase and polarization requirements.

Silence Is Golden: Versatile Deep Part Marking of Hard Materials

The C-Series Silent Scribe marking system and Sound Abatement System from Columbia Marking Tools quietly marks new types of alloys, steels, high-strength low-alloy steel (HSLA) and different formulations of casting materials that require versatile marking pressure capabilities.

High Speed Metal or Plastic Marking with Superior Edge Quality

For high quality customized marking or engraving, the TruMark 5020 fiber laser marker from TRUMPF converts high pulse frequencies up to 1 MHz into high speeds for short marking processes.

How to Make Permanent Part Marking Easy

For directly marking small parts up to full sheets, X Series, Tag Master 3 and KM-1207 benchtop dot peen marker systems from Kwik Mark can process flat, curved and irregular surfaces on materials ranging from hardened tool steels to delicate plastics.

Fiber Laser Marking for High Volume Production

The versatile, easy-to-operate XL-Box from SIC Marking USA uses a high powered, pulsed-wave ytterbium-doped fiber laser for shallow or deep markings of alphanumeric codes, barcodes and 2D Data Matric codes on all metals and some plastics.

SIC Marking Acquires Zaniboni

This deal expands their marking and laser traceability applications for the automotive and mechanical sectors.

Portable Dot Peen Marking Device for Round Surfaces, End of Parts and More

The MarkinBOX Patmark battery-operated cordless part marker from E.L. Simeth | MB Metal Technologies uses a solid carbide pin to mark on materials up to 62 RC, easy-to-use software that manipulates the size, depth and speed of each mark, and adjustable or fixed quick-change fixtures that hold it to the part with magnets, clamps, etc.

Precise Laser Marking of Parts Without Fixtures

Laser marking stations from FOBA use vision-based technology with an integrated camera to reproduce a mosaic-like tiling of the entire marking field, including the displayed parts to be marked, which are then laser-aligned and laser-marked with high precision without using expensive fixture devices.

TRUMPF Strengthens West Coast Presence

They plan to open a new technology center in Costa Mesa, CA, in early 2019.

Sheet Metal Marking Review

Demands are growing for sheet metal fabricators to mark their parts during production for product traceability in the field and better efficiencies in the shop, but many part identification systems can add an unnecessary secondary process. Whenever possible, consider finding ways to incorporate part marking into a manufacturing step that is already required. Here are some ways to use the equipment that you already have.