Other Gauges and Gauging Equipment

Filter by Process Zone:

High Resolution Laser Weld Monitor for Spot or Seam Welds

The compact, lightweight MM-L300A Laser Weld Monitor from Amada Miyachi detects gaps between parts, missing parts, over-penetration, incorrect focus and cover gas absence, providing operators feedback on laser weld quality.

Automation and Metrology

To remain competitive, more shops are searching for ways to better utilize their quality workforce and supplement them with automation. But Ken Myers of Mitutoyo America explains that what automating metrology means to one person might not mean the same to another.

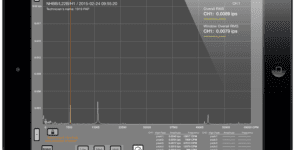

Predictive Monitoring Moves to The Next Level

VibePro 24/7 online vibration and temperature monitoring technology from GTI improves data collection for rotating equipment and bearing health, allows users to easily change assets from route collection to online data collection, clones machines, points and plant areas, and generates long-time waveform for ultrasound display.

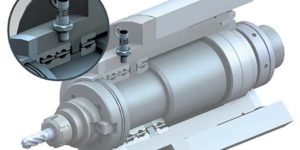

Spindle Diagnostics: Predictive Maintenance at Your Service

Installed directly into the spindle, the miniaturized B-Safe system from Diamond Industrial Tools uses vibration and temperature analysis for real-time monitoring of anomalies, predicting malfunctions and reducing machine downtime.

R&R Fixtures Changes Name

They become Renishaw Fixturing Solutions, LLC, as part of the final phase of integration into the Renishaw business.

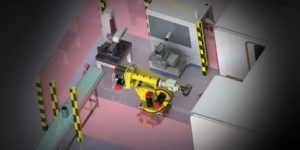

Smart In-Process Monitoring of Stamping and Forming Operations

Brankamp X7 “smart” in-process monitoring systems for cold and hot forming, thread rolling and stamping operations from Marposs use AI to quickly monitor machine setups and effectively control machine performance by detecting manufacturing faults, as well as part or tool variations.

Liebherr Acquires Wenzel GearTec

They can now include gear measuring technology with their gear cutting and automation systems.

Next Generation Spindle Alignment for Lathes, Turning Centers

Remarkably easy to use, extremely fast and highly accurate, compact and versatile L-702 and L-702SP spindle alignment lasers from Hamar Lasers reduce tooling costs, scrap rates and downtime to increase throughput, cut costs and boost productivity.

Blum-Novotest Appoints New Regional Managers

Brian Morris manages sales and service in the Southwest U.S. while Andrew Nichols manages the Midwest.

Measure Gears with Different Diameters Without Mechanical Retooling

For measuring flexibility on the shop floor, the M62 Flex manual bench gauge from Marposs uses a universal reference to locate each part and soft-touch engagement with the gear being measured to prevent any potential damage from contact.

High Throughput Automatic Vision Inspection of Repetitive, Larger Parts

The 3-axis AV450 Automatic Vision System from Starrett is so versatile, accurate and fast that users can cost-effectively achieve high throughput inspection of repetitive, larger parts, as well as routine quality assurance.

Hoffmann Group Celebrates Centennial

Their growing $1.1 billion business now has over 3,000 employees.