Other Gauges and Gauging Equipment

Filter by Process Zone:

Why You WANT Variable Gage Analysis (GR&R) Results

Some manufacturers shy away from conducting gage repeatability and reproducibility (GR&R) studies because the results are inconsistent. But because variability is unavoidable, your goal is to calibrate that measuring device to consistently return an acceptable range of results.

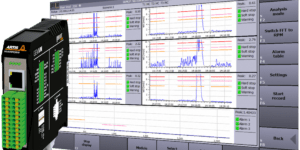

Split-Second Response Enables Predictive Maintenance

The Artis GEMVM from Marposs is a stand-alone spindle-monitoring module that aids in predictive maintenance. Runs on Windows machine control panels or Siemens Linux systems and integrates with Marposs’ Genior Modular monitoring system.

Compact Inverters Optimize Machining Performance

In addition to a wider screen that allows for a split view, Gen 3 drives for Heidenhain’s TNC 640 control system allow for jig grinding and trochoidal milling capabilities on smaller machine tools.

Remote Tool-Monitoring System Provides Real-Time Machine Control

Caron Engineering’s browser-based TMAC 3.0 enables real-time monitoring and system control from any network-connected device for any machine tool brand. It’s ideal for unattended CNC machining because no operator intervention is required.

Broken-Tool Monitor Doesn’t React to Nuisance Faults

Allora International’s PCS-100 sensor kicks in only when a drill, tap, reamer, or end mill breaks, not when chips are accumulating; and ignores common tool-to-tool diameter differences. Speeds exceed 80 cycles/minute to keep up with the fastest machines.

Next-Generation Hand-Held Electronic Micrometers

The 733.1 outside micrometer is one of more than 100 new hand-held measuring tools from L.S. Starrett. The products feature enhanced electronics, ergonomic design, larger readout display, and longer battery life thanks to auto-shutoff.

Real-Time Fluid Monitor Prevents Unnecessary Downtime

A thousand times more accurate than a typical handheld refractometer, Quaker Houghton’s self-contained continuous concentration monitor is an easy-to-use, low-maintenance way to maintain appropriate metalworking fluid levels.

Meter Measures Compressed Air Pressure and Flow

Displaying values on a bright LED screen, Pressure Sensing Digital Flowmeters from EXAIR come with everything you need for installation. You can add another layer of protection for equipment with an optional low-pressure alarm.

Asymmetric XY Stages With Nanometer-Level Precision

ALIO introduces a positioning solution that provides customers with the exact X and Y travel ranges needed for their applications.

Bimetal Reciprocating Saw Blades Triple Cutting Performance

Featuring a reinforced shank that helps resist breakage, 3X Power blades from L.S. Starrett cut metal and other materials more efficiently. A version with heat-treated teeth set at a super-aggressive pitch cuts fast in applications such as demolition and emergency vehicle extrication.

L.S. Starrett Expands Hardness Testing Line with 16 Products

L.S. Starrett’s 16 hardness-testing solutions include seven Rockwell systems, eight Vickers systems, and one Brinell system. Suitable for internal and external testing via dolphin nose design, the No. 3823 and No. 3824 test carbon steel, alloy steel, cast iron, and nonferrous metals per 30 Rockwell hardness scales.

Affordably Priced Handheld XRF Analyzer

The Vanta Element from Olympus Scientific Solutions Americas provides the same fast material- and alloy-grade identification as the line’s other models in a rugged, cost-effective package. The 2.9-lb X-ray fluorescence (XRF) analyzer works in temperatures ranging from 14 degrees F to 113 degrees F (-10 degrees C to 45 degrees C).