Non-Destructive Testing

Filter by Process Zone:

New Solution for In-Line Checking of Pouch Cell Battery Welds

Marposs’ solution can measure thin external plastic layers starting at 1 µm, as well as accommodate thickness variations due to the presence of the tabs in parts of the welding seam.

Marposs Announces MAINDO, the Company’s new Digital Platform

The platform shares and enhances data generated by Marposs systems focused on quality control, production processes and environmental conditions.

Augmented Reality Unit Easily Retrofits Into Existing Stereo Microscopes

Evident’s SZX-AR1 allows an assembler to work without removing their eyes from the oculars or memorizing complex directions.

Mahr’s New Millimar® C 1202 Compact Amplifier

Product is a full feature, configurable, low-cost, digital length evaluation amplifier for high precision measurements in inspection or production environments.

New Olympus OmniScan™ X3 64-Channel Flaw Detector Delivers Improved Power and Performance

The OmniScan X3 flaw detector can process TFM images up to four times as fast as its predecessor, yet comes in the same rugged and easily transportable box.

App for Portable, Fast Weld Inspection of Complex and Oversized Parts

Manufacturers of oversized metal parts, from pressure vessels to wind turbine blades, must validate new-fabrication welds according to stringent international standards. Inspection bottlenecks can slow down production, with delays stretching into months.

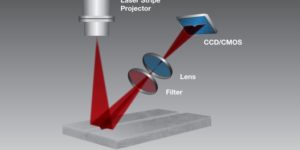

Improving Tube Welding with Laser Inspection

Laser weld inspection systems using 3D imaging can improve productivity and quality control of ERW and HFI tube welding by working in conjunction with other NDT testing.

Zetec Introduces New Phased Array Ultrasound Testing System

The new Emerald™ is an industrial-grade phased array ultrasonic testing (PAUT) system with a powerful, versatile total focusing method (TFM) image processing capability.

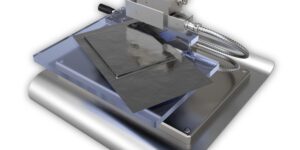

‘One-Button’ Advanced Rockwell Hardness Tester

Buehler’s Wilson RH2150 is easy to program and offers an intuitive software interface with Buehler’s DiaMet hardness testing software. Use the external footswitch with the actuator-mounted clamping device to clamp and activate either manual or automatic start, as well as to release manually or automatically after test.

Seamless Workflow from CT Scan to Full Statistical Analysis

Volume Graphics integrates Q-DAS’ qs-STAT statistics software with computed tomography (CT) scan data analysis to provide the basis for a deep assessment and continuous improvement of industrial production processes.

Hardness Tester Supports Two Measurement Protocols

Mitutoyo America’s HR-600 does both Rockwell hardness testing and Light Force Brinell testing, expanding the range of available measurements. It’s the company’s first hardness tester with a moving head.

Affordably Priced Handheld XRF Analyzer

The Vanta Element from Olympus Scientific Solutions Americas provides the same fast material- and alloy-grade identification as the line’s other models in a rugged, cost-effective package. The 2.9-lb X-ray fluorescence (XRF) analyzer works in temperatures ranging from 14 degrees F to 113 degrees F (-10 degrees C to 45 degrees C).