Metal Forming & Fabricating

Filter by Process Zone:

New Paint Atomizer for Efficient and Sustainable Paint Shops

ABB launches new paint atomizer which increases transfer efficiency up to 10% with a minimum 30% reduction in paint waste to support sustainable operations.

Davi to Feature e-POWER Fully Electric Steel Plate Roll Machine at FABTECH 2024

Innovative machine offers unprecedented performance and precision

in a compact energy-efficient package.

Wintriss Controls Group Expands Tennessee Sales and Service Representation

Wintriss distributor Midwest Press and Automation (MPA), LLC (Lansing, MI) has now expanded its coverage to include Tennessee, adding to its existing territory that includes Michigan, North Carolina and South Carolina, Virginia, Illinois, Southern Ohio and Kentucky.

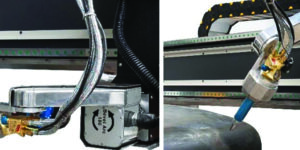

New Tecoi BevelArc 3D Increases Cutting Reach Capability to 90 Degrees

With the new BevelArc 3D, users can perform continuous beveling by tilting, without unnecessary torch turning.

Rethink Robotics Launches Detachable Mobile Manipulator Robot

The Rethink Riser mobile manipulator robot (MMR) allows a single AMR to serve multiple stationary cobot applications.

Pipe Beveling Machine for Super Duplex and Highly Alloyed Heavy Pipe

The Dictator II MILLHOG Pipe Beveler is an I.D. clamping welding end prep tool designed for performing any angle of prep on super duplex and highly alloyed pipe from 4.5” I.D. to 24” O.D.

FABTECH 2024 Tube & Pipe

Fiber lasers and profiling equipment will be showcased in Orlando at Fabtech.

FABTECH 2024

FABTECH will make its premiere showcase in Orlando, Fla., October 15-17, 2024!

FABTECH 2024 METALFORM

The latest metalforming technology will be on display at Fabtech.

FABTECH 2024 Forming & Fabricating

The Latest Technology in Forming and Fabricating will be on display at Fabtech in Orlando.

FABTECH 2024 Automation

Automation solutions will be on display at Fabtech in Orlando.

A Primer: Understanding the Technology and Benefits of Waterjet Cutting

Due to their flexibility, precision, edge finishes, eco-friendliness and more, waterjet systems are gaining popularity as one of the top technologies for cutting.