Measurement & Inspection

Filter by Process Zone:

Checking the Stamp of Quality on Powertrains

One automotive powertrain supplier uses this mobile inspection workstation from Creform for inspection, process and part checks, and the fulfillment of paperwork right at their stamping machines – right near the point where a quality check makes the most sense and can have the greatest impact.

Able Machine Tool is New England Distributor for AIMS

They now sell and service Revolution series CMMs.

Hexagon Earns Design Award

Their WLS qFLASH vision measurement system wins the Good Design Award from the Chicago Athenaeum Museum of Architecture and Design.

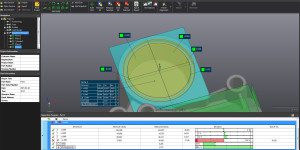

Automating GD&T Principles and Practices Into Inspection

The advanced software in these new shop floor inspection systems integrates geometric dimensioning and tolerancing parameters into the measurement process to improve the assessment of functional precision in the parts being measured.

Next Generation Coordinate Measuring Machine

The XM Series handheld probe coordinate measuring machine from Keyence easily installed in any environment to perform intuitive 3D measurements with high accuracy using advanced optics, image processing and structural design.

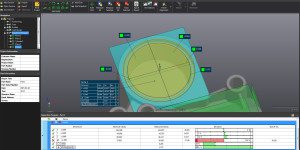

Automated Shop Floor Inspection System

The programmable CMM Master automated shop floor inspection system from Verisurf combines a complete coordinate measurement CAD system with 3D surface modeling, traditional 2D drafting and 3D model associative GD&T with the Equator comparative gauge.

3D Inspection Software for Intuitive Contact and Non-Contact Measurement

VXinspect intuitive 3D inspection software from Creaform includes all of the tools for first article inspection and quality control.

Going Deep

There may be many ways to check a depth dimension on a part, but the fastest and most accurate is with the digital depth gage. Here are some that can meet your deepest needs.

Computerized Measuring Tools

The Ultra-Cal III Electronic Depth Gage from Fowler measures from 0-12 in with improved electronics, including direct RS232 output.

SPC and Data Tracking

The ABSOLUTE Digimatic Depth Gage from Mitutoyo can keep track of the origin point once set for approximately 20,000 hours (three years) under normal use.

Communicate Part Function More Clearly with GD&T

When print tolerances use geometric dimensioning and tolerancing to clearly communicate functional requirements – such as how a hole’s position can vary and still allow for assembly – the tolerances can be made as large as possible without impacting part function.