Measurement & Inspection

Filter by Process Zone:

Liebherr Acquires Wenzel GearTec

They can now include gear measuring technology with their gear cutting and automation systems.

Mahr Inc. Opens New Regional Customer Center

Their new Southeast Regional Customer Center is in Greenville, SC.

Advanced Machine Control and Part Traceability for the Smart Factory

Ideal for IIoT applications, the NX1 controller, HAWK MV-4000 smart camera, handheld HS-360 DPM reader and MicroHAWK ID-45 reader from Omron integrate machine control and part inspection operations seamlessly with quality management and safety systems.

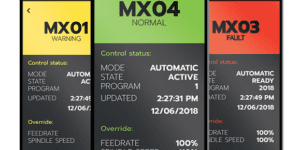

Remote Monitoring of CNC Machines from Handheld Device

Users of the Integrated Machine Analytics mobile app from Mitsubishi Electric Automation can do real-time monitoring and analysis of CNC functions on all MTConnect-compliant CNC machine tools in their facility to keep production on schedule and eliminate potential issues.

Measurement Systems with Open Communications

Diameter, Ovality, Eccentricity, and Flaw Detection measurement systems from LaserLinc use OPC communications protocol that is compatible with Manufacturing 4.0 and IIoT to capture, modify and move data from different systems.

Create A Community for Sharing Metalworking Automation

Using the HKP Mobile App from Haydon Kerk Pittman, technical information and other resources on linear and rotary solutions can be easily shared among colleagues and teams for automation in metalworking, inspection and material handling applications.

Tool Measuring Systems and RFID Working: A Powerful Combination

Efficiently moving information around your shop floor is more important than ever. Connected through RFID, a shop can now use a tool presetter to monitor things never monitored before and use that data to fine-tune processes, reduce inefficient costs like scrap and waste, and make the factory floor smarter, streamlined, far more efficient and competitive.

What Does “Collaborative” Really Mean?

Human-robot collaboration is changing manufacturing operations by helping shops deal with competitive pressures and a lack of skilled labor, but it is not a “one size fits all” solution. Before you invest, consider the different forms of robotic collaboration and how they apply to your entire application.

Mitutoyo America Joins PDES Consortium

They will work to improve CAM, inspection and quality operations for manufacturing.

Hexagon Breaks Ground on New Center of Excellence

This facility in Novi, MI, expands their presence in the Midwest.

API Partners with Kadan

This deal will expand distribution and metrology services to the West Coast for Radian Laser Trackers.

Absolute Machine Partners with Sussex Tool & Supply

This deal gives Absolute better proximity to customers in both Wisconsin and Illinois.