Measurement & Inspection

Filter by Process Zone:

Starrett Appoints New VP of Metrology Systems

David Allen has been tapped to lead the high-end metrology businesses for the Athol, Mass., manufacturer.

Smooth Operator: Surface Finish Measurement

Take a closer look at some of the latest advances in surface roughness measurement that can help improve the manufacturing quality of parts.

Never-Before-Possible Roughness Measurement

A MarSurf GD roughness measuring station from Mahr Inc. can do profile and waviness evaluations in addition to surface roughness evaluations on larger parts or a series of smaller parts staged together – all on the same machine.

Measuring Small Components

The Flying Spot SurfaceMeasure 201FS laser sensor from Mitutoyo uses a point scanning method to achieve high reproducibility, best-in-class scanning accuracy and a high data acquisition rate for inspection and reverse engineering of small components.

Optical Inspection of Cylinder Bore Surfaces

The Hommel-Etamic Toposcan system from Jenoptik can automatically measure the size of porosity and blow holes, stroke reversal radius, laser pocket structures, roughness of bore walls, torn and folded metal and cross-hatch angles.

API Launches New Business

Their new recertified laser tracker business allows low-cost access to portable measurement technology.

Hexagon Partners with University of Rhode Island

They collaborate on student programs for advanced manufacturing.

Mitutoyo Partners with Titans of CNC

Their metrology equipment will be featured in the free project-based education platform.

Automated Metrology

Automating measurement lowers operating costs, supports consistent throughput, improves lean manufacturing capabilities and improves product quality. Here are some different levels of metrology automation that might be a fit for your shop.

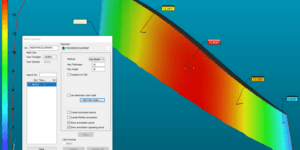

Measurement Software for a Smarter Factory

PC-DMIS 2019 R2 measurement software from Hexagon Manufacturing Intelligence improves user convenience and productivity when intuitively creating measurement routines or executing them in the factory.

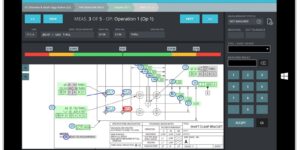

Quality Management Software Moves Toward Quality 4.0

Inspection Manager from High QA automatically extracts GD&T requirements from 2D drawings and 3D models, digitizes prints with automatic ballooning, creates inspection plan reports and stores all the information and measurement tools in a centralized database.

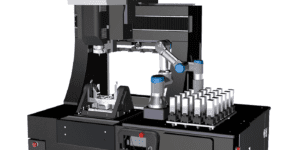

Automated Optical CMM with Cobot

The optical µCMM from Bruker Alicona can measure extremely tight tolerances with high accuracy using a six-axis cobot arm to automatically pick, place, measure and sort (ok/not ok) parts in production.