Measurement & Inspection

Filter by Process Zone:

Automated EMC Test System for Both 5G Frequency Ranges

The TS8996 RSE from Rohde & Schwarz uses the company’s Elektra EMC test software, which has been upgraded with measurement and calibration routines for 5G development and compliance tests. The system enables fully automatic emission measurements on wireless communication equipment.

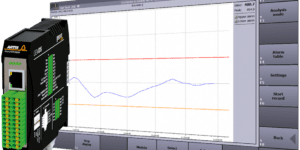

Prevents Machine Damage by Monitoring Spindle Elongation

With four monitoring modules, the Artis GEMDS system from Marposs provides real-time feedback on spindle characteristics that’s critical to avoiding out-of-tolerance parts. The system easily integrates into existing controls, network environments, and Industry 4.0 solutions.

Spindle Optimization to Prevent Drawbar Failure and Downtime

Monitoring drawbar force is fast and easy with JM Performance Products’ ClampForce gage. With gage heads available in four ft/lb configurations, the gage is sold as a complete kit in a heavy-duty toolbox.

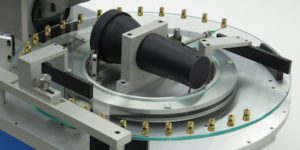

High-Accuracy Ring Encoder Resists Contamination

The Heidenhain ERM 2203 is ideal for contaminated environments and applications that don’t require an optical encoder’s accuracy level. The magnetic ring encoder retains the 200 µm signal period, but with approximately 30% less graduation error.

CT Scanner Produces 3D Data, Fine Details of Light Metal Parts

Exact Metrology is distributing the German-made GOM CT scanner in the U.S. In addition to controlling the device, the scanner’s software analyzes and provides high-resolution internal as well as external component geometries in 3D.

Measuring Offline Takes 1 Minute, Not 15

Big Kaiser’s entry-level Speroni STP Essentia tool presetting system is efficient and easy to use. Operators measure and match cutting edges of tools to the job right next to the machine tool.

Measure 48-Inch Components on the Shop Floor

American Precision Gauge solves an age-old measuring limitation for shafting, piping, tubing, and other long components. Use the digital caliper for quality control or build it in as a setup gauge or touch-off.

Bringing Flexibility to 100% Inspection of Precision Turned Parts

A Michigan automotive component supplier finds the ideal tool for quickly and confidently ensuring 600 active parts meet zero-defects requirements. Two Resec Systems ShadowGage Sorters paid for themselves within six months.

Asymmetric XY Stages With Nanometer-Level Precision

ALIO introduces a positioning solution that provides customers with the exact X and Y travel ranges needed for their applications.

Magnetic Encoder System for Absolute Accuracy of Position

With Drive-Cliq interface, Balluff’s measuring system continuously checks quality and isn’t affected by heat or dirt.

Hexagon to Acquire CAE Software Maker Romax Technology

Adding Romax’s expertise in electromechanical drivetrain design and simulation to its Manufacturing Intelligence division will, says Hexagon, enhance its Smart Factory Solutions.

Bimetal Reciprocating Saw Blades Triple Cutting Performance

Featuring a reinforced shank that helps resist breakage, 3X Power blades from L.S. Starrett cut metal and other materials more efficiently. A version with heat-treated teeth set at a super-aggressive pitch cuts fast in applications such as demolition and emergency vehicle extrication.