Measurement & Inspection

Filter by Process Zone:

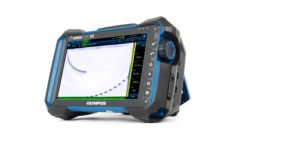

Flaw Detector Combines Multiple Features

OmniScan phased array ultrasonic testing (PAUT) instruments are known for power, reliability, and ease of use. Whether inspecting pipes, welds, pressure vessels, or composites, the OmniScan X3 flaw detector from Olympus enables users to complete their work efficiently and interpret flaws with confidence.

3D Laser Scanning Supports COVID-19 Response

Two NVision Inc. projects demonstrate the growing role of noncontact scanning/measurement technologies in the race to create new products that minimize exposure to the novel coronavirus.

Quickly and Easily Measure Carbide Tools and Metal Blanks

Confirm tolerances without gauge remastering with the Aeroel MECLAB.T40 from Marposs. The benchtop laser measurement system doesn’t require a PC, so it’s ideal for use on the shop floor.

Lab-Quality Measurement Anywhere You Need It

Equipped with a 16-bit high-dynamic-range (HDR) camera, Mahr’s updated MarSurf CM mobile optical surface metrology tool offers the highest-speed, highest-resolution confocal measurements on the shop floor and in the field.

‘Total’ QA/QC with Autonomous Machine Vision (AMV)

The developer claims its Inspekto S70 is the first truly autonomous inspection system. Driven by artificial intelligence engines that use good samples to identify noncompliant parts, the Inspekto S70 installs in minutes and is about one-tenth the cost of traditional machine vision solutions.

Nanometer-Level Motion Control for Micromachining

As micro-processing quality requirements become more demanding, legacy systems don’t always meet accuracy and repeatability specifications. Built around ALIO’s 5-axis laser gimbal, 6D Laser’s integrated infinite field of view (IFOV) system increases processing speed while eliminating errors from field stitching.

Turnkey Robotic Inspection Cells

The scalable 3D quality inspection (3DQI) joins the FlexArc and FlexLoader in ABB’s growing portfolio of smart and flexible solutions. Designed to accelerate testing of automotive, aerospace, heavy machinery, and construction workpieces, the hardware/software solution also enhances quality and reduces waste.

Why 5-Axis Metrology is Crucial to Creating a Smart Manufacturing Network

Part complexity, tougher quality requirements, and calls for 100% parts inspection are on the rise, straining the capabilities of conventional 3-axis coordinate measuring machines (CMMs). Adding A and B axes via the industry’s only multisensor probe to a CMM’s X, Y, and Z axes increases surface speed and shortens measurement cycles.

Easy-to-Use Laser Weld Monitor

Amada Weld Tech’s MM-L300A laser weld monitor improves weld performance by giving operators real-time feedback on production errors such as gaps between parts, missing parts, over-penetration, incorrect focus, and cover gas absence. The unit’s software simplifies setup and analysis.

Easy-to-Use Software Package Automates Touch Probing

Developed to support both Fanuc and Siemens CNC systems, Marposs Corp.’s software package improves machining operations by automating measurement processes and reporting for the company’s optical and radio touch probes.

Machine Monitoring Software Integrates With MES And ERP Software

Marposs Corp.’s C-THRU4.0 software collects, processes, and integrates data from a fleet of machine tools via a single hub that integrates with manufacturing execution system (MES) and enterprise resource planning (ERP) software.