Measurement & Inspection

Filter by Process Zone:

Safely Inspect Small-Diameter Tube and Pipe Welds in Real Time

Suitable for outside diameters of 0.2 to 8 inches (5 to 200 mm) and maximum bead widths of 0.4-inch (10 mm), Xiris Automation’s WI-2200 weld inspection system incorporates a Class 2 laser that won’t injure employees.

Smart Visual Inspection Technology Meets Metrology Products

A new Mitutoyo-Kitov agreement will lead to the integration of Kitov technologies in Mituoyo’s metrology solutions. Look for future development of more solutions to come from the new partners as they combine Mitutoyo’s measurement technologies with Kitov’s planning and inspection technologies.

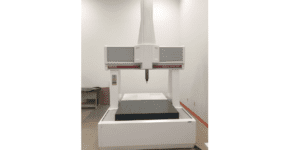

Acquisition Expands AIMS Metrology’s Service Footprint

Now under AIMS ownership, Measurement Specialties Inc. has supported CMM brands including Sheffield – as retrofitting and upgrading business has increased over the last year, AIMS is now poised to broaden its customer service offerings.

Handheld Analyzer For Metal Alloy Analysis

Smaller and lighter than other laser-induced breakdown spectroscopy (LIBS) analyzers, Rigaku Analytical Devices’ KT-100S identifies difficult materials including low-alloy steels, stainless steels, high-temperature alloys and lithium.

Ultrasonic Thickness Gage with Temperature Compensation

The 38DL Plus with 38-Link wireless adaptor for connecting to the Olympus Scientific Cloud (OSC) saves time and money by minimizing human error and optimizing data management.

Handheld Sensor Reliably Measures Countersinks on Various Surfaces

LMI Corp.’s LaserGage HS742 3D sensor is a 3D laser profiler and that uses blue-laser technology and application-specific algorithms to overcome the challenge of measuring countersinks on solid, translucent, shiny, and opaque surfaces with repeatable results.

Updated Software Expands Force Gage Versatility

Ametek’s Chatillon DFS II Series digital force gage with ForceTest 2.0 software gives the operator a highly flexible testing system while additional functionality. The operator also benefits from live test graphs and data analysis.

All-in-One Kits for Quality Assurance Using Universal Robots’ UR3e Cobot

Designed for Universal Robots’ UR3e cobot arm, the Q-Span Workstation from New Scale Robotics comes with everything necessary to automate small-part measurement inspection. You can improve gage R&R and boost capacity without adding headcount.

Why You WANT Variable Gage Analysis (GR&R) Results

Some manufacturers shy away from conducting gage repeatability and reproducibility (GR&R) studies because the results are inconsistent. But because variability is unavoidable, your goal is to calibrate that measuring device to consistently return an acceptable range of results.

100% Inspection on the Manufacturing Line

Streamlining quality inspections just got easier with Olympus’ Vanta iX in-line XRF analyzer that automates material analysis and alloy ID. Metal fabricators get real-time process monitoring in their 24/7 operations.

Two Optical Cutting-Tool Inspection Systems

Omega Tool Measuring Machines adds the Vue with 145x magnification and Vue Lite with 95x magnification to its portfolio of cutting-tool presetting and inspection systems.