Material Handling

Filter by Process Zone:

Robots and Automation Shatter Records in North America

Robotics, machine vision, and motion control applications gave reached their highest levels of growth ever.

Dorner Launches New Multilingual Website

The newly revamped site features a responsive user-friendly interface for better functionality, customer support and easier navigation from mobile devices.

Wildeck Fully Integrates Ladder Industries

Their operations are now identified as Wildeck West and their products are sold through Wildeck material handling dealers and systems integrators across the U.S.

Magnetic Holders for Tool Storage

Magnetic tool holders from Industrial Magnetics keep MIG and TIG torches, grinders, impact wrenches, spray cans and hoses organized, safe from damage and close at hand.

Wildeck Receives Prestigious Supplier Award

They receive the “Most Valuable Supplier” award from MHEDA for exemplary commitment to their dealer network, their employees and their community.

Bunting Magnetics Appoints New General Manager

Kevin Miller now oversees production, inside sales, engineering and purchasing operations in their Newton, KS facility.

Durable Mobile Storage Units for Extreme Productivity

By increasing productivity and reducing costs in material handling operations, these tool storage and transport systems are revolutionizing tool transportation, organization, and storage in the shop.

Daifuku North America Opens New Headquarters

The nearly 77,000 sq ft facility showcases their vast array of material handling systems and equipment and will also be utilized for testing and design.

When to Replace Forklift Forks

The common forklift fork is often overlooked and under-inspected in many shops that are unaware of how often they need to examine their forks or even how to inspect them. This primer explains what to look for and how to replace this critical component of your material handling operation.

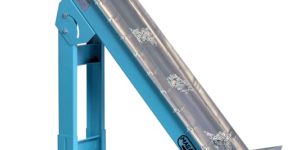

Run Out on a Rail

The chip conveyors in this shop that manufactures railroad car components were falling apart due to jams they couldn’t handle from the bushy stringers of steel chips coming off two turning centers. What could they do? They found the answer in a unique dual-belt stacked conveyor arrangement that reduces or even eliminates jamming problems.

Move Abrasive, Oily Ferrous Chips and Parts with No Jammed Belts or Clean-Out Maintenance

MagSlide Beltless Chip and Parts Conveyors from Bunting Magnetics use ceramic or rare earth magnets hidden beneath a stainless steel slider bed to move metal along the surface. There are no external conveyor belts to jam, tear or wear out, or external moving parts to fail, compromising safety and productivity.

High and Low Capacity Die Carts and Work Stands

The Mini-Titan low capacity standard die cart line from Green Valley Manufacturing has a 250 lb to 2,000 lb capacity range, and their newly designed work stands from the ever-expanding Heavy Duty Titan Industrial Work Horse line has capacities of 500 lb per pair to 100,000 lb per pair.