Material Handling

Filter by Process Zone:

World’s First Robot With Process-Optimized Motion Modes

In addition to providing the longest reach in the high-payload category and featuring a slimmer profile, KUKA’s updated KR Quantec robot offers three software plug-ins to maximize performance, path, and cycle times.

Handling Systems International, Inc. Releases Dealer Quotinator

Online quote tool gives dealers 24/7 access to quotes and drawings. Considering the high demand for H.I.S.’s NikoRail enclosed track cranes, fast turnaround and well as expedited bill of materials to the shop floor will prove valuable to the company and the marketplace.

So Simple Even a Beginner Can Use It: Instant Feedback Minimizes Programming Errors

By automatically calculating the user’s orientation relative to the robot, Yaskawa Motoman’s tablet-based Smart Pendant eliminates the need to use conventional X, Y, Z coordinates. No hard copy manuals required, either.

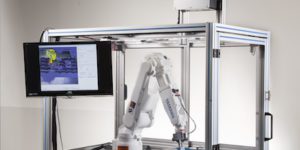

Single-Step Bin-Picking Solution Greatly Lowers Cycle Times

Yaskawa Motoman’s turnkey MotoSight 3D BinPick handling system uses just one camera to identify randomly placed parts. Three camera models are available to cover a range of part and bin sizes.

Autonomous Transporter Forges the Most-Efficient Path Through a Job Shop

The strongest and most recent addition to the LD Series of autonomous mobile robots from Omron Automation Americas moves 550 pounds (250 kg) while enabling manufacturers to control a fleet of 100 robots using a single system.

7-Axis Cobot With Fast Teaching and Simple Controls

Armed with torque sensors in all 7 axes that detect and immediately react to contact with a human coworker, KUKA’s LBR iiwa eliminates the need for safety fences for true human-robot collaboration (HRC).

Complex Sealing And Under-Body Coating Are No Match For This Robot

With a maximum reach of almost 9.5 feet, 33-pound payload, and 7 axes, Kawasaki Robotics’ automotive-industry BU015X robot is ideal for sealing tasks through windows and inside vehicle bodies.

Link Sheet Metal Storage And Processing In One Completely Automated Process

KASTO’s manipulator for automated sheet metal handling saves time and provides cost advantages by seamlessly connecting the company’s fully automatic storage systems with laser cutting machines made by a range of manufacturers.

Air Hoist Lines for Fast Lifting in Demanding Industrial Settings

Move heavy parts, components and material quickly and confidently with two Harrington Hoists models: the TCK Series and lube-free TCL Series. Cast iron housing ensures strength and durability; adjustable limiter automatically blocks air flow when an overload is detected.

Ergonomic Lifting Devices Act Like Extension of the Operator’s Arm

Gorbel’s G-Force and Easy Arm intelligent lifting devices (ILDs) bridge the gap between traditional lifting solutions and completely automated robotic solutions. They provide a combination of pinpoint precision and speed that hoists and air balancers can’t achieve.

Palletizer’s Robot Arm Simplifies Complex Processes

With a compact design that consumes 40% less space, Flexlink’s RI20 can be relocated in a few hours and used in multiple lines in a single day. Meanwhile, operators and robots can safely coexist on the production floor.

Fast-Access Storage Saves the Day for Metal Products Specialist

The increased demand in the cut-to-size sheet segment was making storage space tight at AMCO Metal Service GmbH’s premises in Germany – then they discovered KASTO’s Unigrip 3.0 storage system that increased productivity and fast access to materials and finished parts.