Maintenance

Filter by Process Zone:

Added Value: The Importance of Aftermarket Care

You’ve covered every detail in upfront costs and factory floorspace, but what about technical support and service after production starts? Whether buying one robot or hundreds, having access to diverse support services to ensure peak robot performance is vital to maximizing your return on investment. Here’s why.

Cleanliness is a Virtue

This old proverb rings true for your plant more than ever: Take a closer look at how good housekeeping practices positively impact profit, productivity and purpose in metalworking operations.

Smart Proximity Sensors Improve Predictive Maintenance

E2E NEXT proximity sensors from Omron feature exceptionally long sensing distances and IoT functionality that helps shops reduce potential causes of unplanned downtime.

Perpetual Wireless Equipment Health Monitoring

The Vero equipment monitoring system from Nikola Labs promises to simplify maintenance and perpetually power sensors without wires or disposable batteries.

The Future of Industrial Hydraulics

Achieving energy savings up to 60 percent in medium performance applications up to 30 kW, the compact CytroBox hydraulic power unit from Bosch Rexroth integrates IoT technologies for connectivity, condition monitoring, data analysis and more.

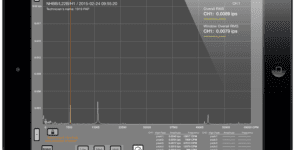

Predictive Monitoring Moves to The Next Level

VibePro 24/7 online vibration and temperature monitoring technology from GTI improves data collection for rotating equipment and bearing health, allows users to easily change assets from route collection to online data collection, clones machines, points and plant areas, and generates long-time waveform for ultrasound display.

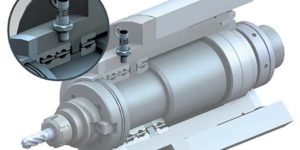

Spindle Diagnostics: Predictive Maintenance at Your Service

Installed directly into the spindle, the miniaturized B-Safe system from Diamond Industrial Tools uses vibration and temperature analysis for real-time monitoring of anomalies, predicting malfunctions and reducing machine downtime.

AI-Driven Remote Machine Monitoring

Using the Service predictive analytics application from MachineMetrics, OEMs and equipment distributors can transform their approach to service with the ability to see, understand and take action on their customer’s real-time machine data from anywhere at any time.

A Safer Environment in Welding Operations

For applications that produce or process welding fumes and fine, fibrous and heavy dusts, the GSX industrial dust collector from Camfil exceeds OSHA mandates for indoor air quality and meet NFPA and ATEX standards.

Air Flow Amplifiers Extract Dust and Fumes with No Moving Parts

High-flow, bladeless Air Flow Amplifiers from Vortec extract smoke, fumes, and debris in a wide range of applications, with no moving parts to wear out or break down.

Remove Harmful Airborne Fumes and Particulates

Source-capture fume extractors from Sentry Air Systems protect the operator’s breathing zone from pollutants caused by welding, brazing, soldering, grinding and other applications.