Machine Controls

Filter by Process Zone:

Perpetual Wireless Equipment Health Monitoring

The Vero equipment monitoring system from Nikola Labs promises to simplify maintenance and perpetually power sensors without wires or disposable batteries.

The Future of Industrial Hydraulics

Achieving energy savings up to 60 percent in medium performance applications up to 30 kW, the compact CytroBox hydraulic power unit from Bosch Rexroth integrates IoT technologies for connectivity, condition monitoring, data analysis and more.

AI-Driven Remote Machine Monitoring

Using the Service predictive analytics application from MachineMetrics, OEMs and equipment distributors can transform their approach to service with the ability to see, understand and take action on their customer’s real-time machine data from anywhere at any time.

Okuma Completes Smart Factory

Their smart factory expands their capabilities and production efficiencies for machining centers and double-column machines.

Caron Engineering Joins OMIC R&D

They have partnered with the organization to become its 26th member.

Heidenhain Opens Training Center

Their new TNC-CNC Academy is available for users at all levels, including those interested in 5-axis machining.

Touch and Go: Machine Controls

Touchscreen control functions used in smartphones and tablets are now being integrated into CNC machine tool controls to help make programming more intuitive and fast, to navigate quickly and intuitively through long lists, programs, tables and other content.

Can We Talk? Conversations Between Machines Get Deep (Part One)

Across the emerging Smart Factory, connected systems are networking production processes from design to final delivery. Conversational programming makes it quick and easy for operators to generate programs at the machine, while other connected systems exchange and use information about tool management, batch processing/scheduling, machine monitoring, quality assurance and more.

Can We Talk? Conversations Between Machines Get Deep (Part Two)

Across the emerging Smart Factory, connected systems are networking production processes from design to final delivery. Conversational programming makes it quick and easy for operators to generate programs at the machine, while other connected systems exchange and use information about tool management, batch processing/scheduling, machine monitoring, quality assurance and more.

Artificial Intelligence: The Next Generation of Communication

Manufacturing generates an unprecedented amount of data, creating an urgent need for shops to augment human analysis with AI that can unlock its value, learn from the historical knowledge embedded in their organizations, and help them remain competitive in the future.

Control Software Boosts Memory and Connectivity – At No Extra Cost

By offering greater functionality standard at no cost, PathPilot CNC Control Software from Tormach overcomes two of the biggest barriers in a CNC investment: cost and capability.

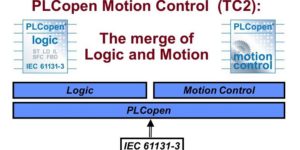

Open Automation Standards Simplify Motion Control Machine Programming

Using software standards from PLCopen, engineers can quickly and efficiently implement complex motion and machine control in high speed multi-axis machining and other industrial automation applications.