Lubricants, Coolants, Metalworking Fluids

Filter by Process Zone:

Industrial Innovations Expands Sales Network

Die Maker Solutions now represents their lubrication systems for metal stamping and forming shops in Texas and Oklahoma.

How to Manage Precise Temperature Control of High Powered Lasers

The Intelligent Laser Cooling System from Glen Dimplex Thermal Solutions delivers smart technology, improved uptime and a reduced overall footprint that eliminates the need for multiple chillers.

How to Defeat Downtime

No one is happy when a machine goes down because of tooling issues – wasted time that is even more frustrating when it’s avoidable. Arrow Storage Products found a way to significantly reduce their machine downtime and cut their average tooling downtime per week due to tooling by 70 percent.

Keeping it Cool: Why Machines Depend on Chillers, and Chillers Depend on You

Lax water maintenance has a huge potential downside in laser cutting machines: bad water could lead to extreme overheating and complete failure of the laser. Here are some other reasons why keeping cool and remembering to change the chiller water will get the most work out of your machinery at the lowest cost of ownership.

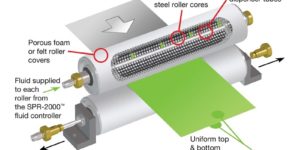

Stock Lubricator Delivers Cleaner Floors and Presses, Reduces Lubrication Costs

With improved guarding that helps guide material when loading coil stock or feeding blanks, the updated Uni-Roller stock lubricator from Unist delivers 50 percent or better reduction in lubricant consumption for cleaner floors and press windows.

Coil Lubricating System for Stamping Improves Accuracy and Reduces Costs

The Spra-Rite UltraCoat non-contact spray system from Industrial Innovations is designed for easy coil feed installation and press control communication for reliable, economical application of lubricant to stock prior to stamping to help improve accuracy and reduce overspray and consumption.

Environmentally Safe Cutting Lube Increases Tool Life

Versatile RotaGel Cutting Lube from Hougen increases the tool life of annular cutters, taps, drills, saws, reamers and endmills used on carbon steel, stainless steel, Inconel, Hastelloy, titanium, aluminum and other alloys and exotics.

MQL System Delivers Process Control and Performance

The Quantum minimum quantity lubrication system from Unist interfaces directly to machines to give shops reliable digital control of cutting lubrication down to a fraction of a drop to fine-tune machining processes, accurately measure and control usage, and share settings between multiple machines.

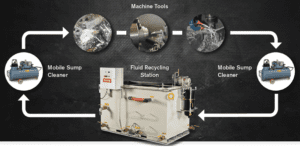

Coolant Recycling Takes Center Stage

Are you concerned about the rising expenses associated with your waste management? Do you need a more effective and profitable way to reclaim and recycle your valuable metalworking fluid? Modern fluid reclamation systems use innovations that can provide a fast return on investment while improving your profits, equipment life and employee safety.

STLE Elects New President

Greg Croce of Chevron Products now leads the society in emphasizing education, technical innovation and global advocacy in tribology and lubrication.

How to Reclaim Cutting Fluids, Coolants and Oils from Metal Chips and Turnings More Efficiently

The CP-2202-CHIP Heavy Duty Industrial Compactor from SP Industries removes fluid from both the compaction chamber and the compaction container and pumps it to a single, sealed collection tank for later recycling or holding.

Sun Chemical Increases Plant Capacity

Their Kashima plant in Japan has increased production capacity of additives for metalworking fluids used in cutting, forming and rolling.