Lubricants, Coolants, Metalworking Fluids

Filter by Process Zone:

Up Your Game with Reliable and Safe Cleaning and Lubrication Products

Fabricators can attain spotless and unsoiled parts and machinery in an environmentally responsible way.

Five Ways to Improve ROI with the Right Maintenance Products

Reduce machine downtime and improve efficiencies by using products designed to tackle the most demanding maintenance challenges.

Metalworking Fluids: Less Is More

A targeted and calibrated approach to lubrication ensures fluids arrive exactly where they need to be, when they need to be there, and in the correct amount, ensuring metalworkers are confident in their ability to make good parts.

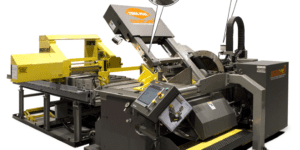

Cutting Fluid Recycling Systems

Keep operations running smoothly and extend tool life with improved fluid maintenance programs.

WD-40 Brand Launches Gear Shop and Summer of Swag Sweepstakes

Official WD-40 Brand merchandise is available to purchase for the first time, and fans of the blue-and-yellow can have a chance to win $100 gift cards each week.

Five Smart Maintenance Tips to Keep Your Machines Humming

With machine shops running at or near full capacity, unscheduled downtime due to machinery and equipment breakdowns can cost time and money – but routine maintenance can keep facilities moving.

Coolant R&D Can Cut Tool Wear

According to Blaser Swisslube Inc. (Goshen, New York), choosing the right metalworking fluid for an application can have wide-ranging and positive effects on tool life, cycle time and workpiece quality.

Automated Monitoring of Coolant Results in Cleaner Machines

Sensors monitor and measure fluid concentration and temperature, two major factors impacting performance.

Track and Control Stamping Operations in Real Time From Wherever You Are

IRMCO Advanced Metalforming Lubricant Technologies’ iNSIGHT enables metal stampers to track the rate of chemical consumption by part and process and compare the data to tool life to pinpoint the actual cost per part for each process in a facility.

Metalworking Fluid Isn’t Just Another Consumable

Formulators spend significant resources to develop coolant that optimizes a machining process based on what materials, machine, and tooling a manufacturer is using. Don’t miss out on the product’s strategic value by being pennywise and pound-foolish.

Extend Your Cutting Tool Investment By Up to 25%

Cutting tools account for 3% to 5% of manufacturing costs, so anything that extends their life will improve profitability. By minimizing waste and freeing employees to perform higher-value work, automated fluid recycling systems pay for themselves in less than a year.

Boron- and Amine-Free Cooling Lubricant

Zeller + Gmelin’s Zubora 30 FD provides excellent drainage with minimal copper release, making the cooling lubricant ideal for machining sensitive copper and aluminum alloys.