Laser Welders

Filter by Process Zone:

ESAB Initiatives Support Students and Careers in Metalworking

WeldItForward, the Paley-James Project and Metal Mentors all support secondary and post-secondary students in technical education, manufacturing and engineering programs.

Amada Miyachi America Expands Applications Laboratory

Their new 85,000 sq ft manufacturing facility is equipped with 11 application-specific labs that support each of their product lines, processing nearly 100 samples per month.

Laser Welding Made Easy

The TruLaser Robot 5020 from TRUMPF provides for easy, cost effective entry into laser welding of simple sheet metal parts to bent profiles and three-dimensional geometry that is commonly produced on machining centers.

Amada Miyachi America Receives ISO 9001 Certification

Their quality management system is certified for manufacturing products in a manner that is consistent, repeatable, and well-suited to aerospace, medical and other customer requirements.

Lean Pulsed Fiber System Welds, Marks and Cuts Metals, Plastics and Dissimilar Metals

The versatile, high power, high speed laser LMWS Pulsed Fiber Laser Welding System from Amada Miyachi America can weld copper to aluminum, aluminum to stainless and steel, and copper to stainless steel.

Laser Welding: How to Reduce Production Costs Before You Even Begin

Knowing how to utilize the increased flexibility gained through laser welding can enable a fabrication shop to tackle tough challenges and creatively solve them.

Advanced Welding Cells for Gearmaking and Automotive Jobs

These new Arnold CNC laser workcells from GMTA are ideal for welding smaller round components and other geometries, including axial and radial seams.

Higher Power Fiber Lasers for Thicker Materials and Faster Speed

Four new LF Series fiber laser welders from Amada Miyachi America address thicker materials or increase processing speed for a given application through continuous wave and modulated fiber laser technology, with both single mode and multimode options.

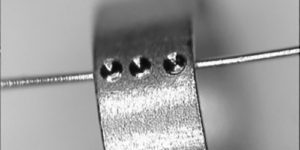

Nd:YAG or Fiber Laser Micro Welding?

There are a number of choices for laser for micro welding. Here are the factors to consider why and when one laser might be chosen over another, and how to select the best option for your specific application.

Coldwater Machine Named Level 1 FANUC Integrator

This status opens up new automation opportunities for them in appliance, automotive, and aerospace applications.

Three Common Questions Concerning Laser Welding in Sheet Metal Fabrication

Many sheet metal fabrication shops still hesitate to invest in laser welding. They are missing out on the numerous competitive advantages and opportunities that it offers over conventional welding processes. Here are some insights that they need to know.

Lasers Handle Cutting and Welding of Complex Parts

This shop welded the seam and cut 100 million holes in 12,100 torches – in six months. That’s not all. Check out the automotive parts they’re making.