Laser Cutting Systems

Filter by Process Zone:

Fiber Laser System Machines 3D Parts

The five-axis LT-FREE fiber laser machine from BLM performs traditional cutting, drilling, punching and milling operations that are normally carried out in sequence on separate machine tools.

The ROI Threshold

What happens when demand for parts from a supplier increases so that an OEM can scale up production? Determining the ideal time to transition to a more economical alternative can be challenging, but a “one-stop” parts supplier can scale with demand, facilitating the transition to hard tooling, mixing and matching metalworking techniques for multi-component assemblies, and incorporating hybrid and secondary tooling approaches to further reduce costs.

Waukesha Metal Products Invests in Fiber Laser Technology

They install a 4 kW fiber laser cutting system in their fabrication facility in Grafton, WI.

TRUMPF Canada Names New Managing Director

Tobias Kuehnle will assume his new role on April 1, 2018.

Cincinnati Incorporated Hires New Sales Engineer

Adam Yborra now serves eastern Pennsylvania, south New Jersey, Delaware, Maryland, and northwest New York.

Economical Processing of Sheet and Plate Material

Advanced laser cutting systems and press brakes from Bystronic can process brass up to 5/8 in thick, mild steel up to one inch thick, and aluminum and stainless up to 1.180 in thick, all with impressive quality and precision to the outermost edges of the metal sheet.

Innovative, High Productivity Fiber Laser Tube Cutting

The TruLaser Tube 5000 fiber laser tube cutting machine from TRUMPF is the first tube cutting machine with a solid-state laser to eliminate the need for a fully enclosed housing, making it quick and easy to load individual tubes and profiles or to remove finished parts while the machine is in operation.

High Production Tube Fabrication

The TL 2665-FL from LVD Strippit efficiently processes round, rectangular, square or other standard tube profiles in lengths up to 26 ft in a range of materials and at optimal speeds using a 2 kW fiber laser.

LaserNett Moves to New Location

Their new 87,000 sq ft facility includes enough land for a 60,000 sq ft expansion in the future.

Laying Groundwork for Great Laser Cutting: Start with the Slats

Though it is often overlooked by equipment users, one of the most critical factors to consistent laser cutting quality is the proper maintenance of the worktable where the cutting process takes place.

Metal Fabrication: The State of the Industry

Shop owners and decision makers are feeling more comfortable with the economic climate and are more willing to make capital investments in new machinery that adds capacity to their operations. Here are some insights into the equipment they will need.

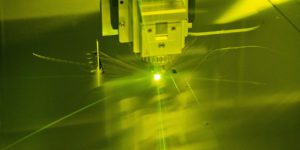

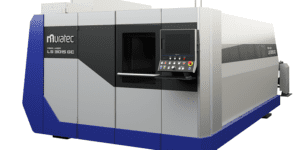

Economical Fiber Laser Cutting of Ferrous and Non-Ferrous Materials

The compact LS3015GC fiber laser cutting system from Murata Machinery uses an integrated flying optics system with internal controls that monitor laser output, laser beam and light reflection for superior cutting of ferrous and non-ferrous materials, including steel, stainless steel, aluminum, brass and bronze.