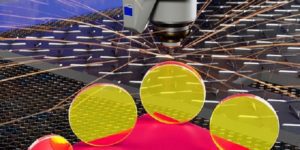

Laser Cutting Systems

Filter by Process Zone:

A Look Ahead

As the metal fabrication business remains strong, watch for more shops to adopt digitization, the principles of Industry 4.0 and integrated process flow as they move toward smaller batch sizes, shorter lead times, high-mix parts to compete – and to address the lack of skilled labor.

Small Actions Make a Big Impact on Cutting Success

Those details that were so important in the beginning slowly lost their importance in a slippery slope toward diminished product quality, lower efficiency and lack of maintenance. Getting back to basics is always the best way to keep a laser tube machine in top condition mechanically and optically, and to avoid a huge problem before it seems insurmountable.

Prima Power Laserdyne Appoints New Regional Sales Manager

Dominic Rickard is their new Western regional sales manager for LASERDYNE equipment.

New Director of Sales for TRUMPF

Jack Pennuto Jr. is now the director of sales for their Laser Division in North America.

The Dream Machine: Fully Automated, Nearly Autonomous Laser Processing

Ideal for Industry 4.0, the fully automated TruLaser Center 7030 from TRUMPF works autonomously over long periods, without any operator intervention for programming all the way to sorted and stacked finished parts. It eliminates collisions involving tilted parts, refinishing work on microjoints, spatter on the undersides of components, and excessive programming work.

Shop Uses Tabs to Save Five Hours on a Single Laser Run

Laser Cutting Services used the recessed tabbing feature in SigmaNEST software from SigmaTEK to save five hours of secondary process time deburring each part post-cut on a run of 4,000 parts.

Large Format Fiber Laser with Air-Cooled Cutting Head and 6 kW Resonator

The flexible automation built into the high speed L3-6020 fiber laser from Salvagnini can process sheets up to 240 in long and up to 80 in wide in sequence, without stopping production and with all setups occurring in masked time.

Fast and Precise Laser Bevel Cutting of Titanium Tubular Bicycle Parts

A Laserdyne 430 BeamDirector fiber laser cutting system from Prima Power Laserdyne precisely bevel cuts the titanium tubing used throughout the Helix Folding Bike so that parts mate perfectly without deburring prior to welding.

Ultra-High-Speed Cutting of Ferrous and Nonferrous Plates

The Electra FL 3015 10 kW fiber laser cutting machine from LVD Strippit provides ultra-high speed cutting of ferrous and nonferrous materials in plate thicknesses up to 1.25 in.

CO2 Laser Lenses for Cutting Thick Steel Plate

Ideal for 200 W to 4 kW CO2 cutting lasers, CO2 Laser Lenses from Laser Research Optics can ship overnight for field replacement of 3 in to 10 in focal lengths and 1 in to 2 in OD sizes with thicknesses ranging from 0.250 in to 0.380 in.

Processing Head with Autofocus for Flat Sheet Fiber Laser Cutting

The compact, lightweight and reliable FiberMINI AF processing head from Laser Mechanisms can process a wide range of materials with automatic, programmable focus.

Precise Laser Marking of Parts Without Fixtures

Laser marking stations from FOBA use vision-based technology with an integrated camera to reproduce a mosaic-like tiling of the entire marking field, including the displayed parts to be marked, which are then laser-aligned and laser-marked with high precision without using expensive fixture devices.