Industrial Cleaning/Waste Removal

Filter by Process Zone:

Heavy-duty Cleaning of Dry Lube, Cutting Oils, Waxes, Grease, Carbonized Soils, Shop Dirt

METALNOX M6310 from Kyzen is a mild alkaline, aqueous cleaning chemistry that is specially designed for heavy-duty cleaning of dry lube, cutting oils, waxes, grease, carbonized soils and shop dirt.

Save Money by Reducing Your Water Footprint

The innovative Extran™ system from Separation Dynamics is specifically designed to clean and recycle mop water and floor scrubber water.

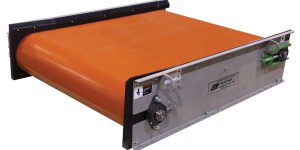

Conveyor Removes Tramp Metal Fines

Bunting® Magnetics has a new line of high-intensity separation conveyors that provide extremely high magnetic field to separate work-hardened 300 series stainless steel from the product stream, increasing separation effectiveness for medical waste and automotive and electronic scrap recycling.

Industrial Cleaning/Waste Removal

This category includes tools and devices used in the safe cleaning and removal of harmful waste materials generated during the fabricating process. Fabricated metalworking processes can generate several different hazardous waste streams, such as oily wastes, heavy metal pollutants generated…

Magnetic, Non-Magnetic Material Handling Systems

These magnetic and non-magnetic conveyors from Magnetic Products provide positive control of ferrous and nonferrous metal stampings, turnings, chips, fasteners and scrap.

Chips and Fines Filtration/Removal from Machine Tools

These new conveyors for metal cutting machine tool chip removal from Jorgensen Conveyors are designed specifically to handle heavy chip loads and large stringy chips and balls of chips generated in milling and turning applications where high work piece stock removal rates exist.

WAY OIL AND COOLANT SEPARABILITY

Because they affect both machining precision and the service life of the metalworking fluid, slideway lubricants are integral to the productivity of modern machine shops. Here are some tips from Mobil Industrial Lubricants on selecting the correct slideway lubricants for your application.

PROPER CARE AND MAINTENANCE

Even though a machine tool spindle is a high-precision machine component, more often than not it is handled carelessly, forced to perform well beyond design limitations, or otherwise abused to the breaking point. Ed Zitney of SKF Machine Tool Services shows how proper care and maintenance can make all the difference in both its operation and longevity in service.

ALL PURPOSE INDUSTRIAL VACUUM DOES IT ALL

The compressed-air 110 gal Reversible Drum Vac™ from EXAIR Corporation handles coolant, hydraulic oils, spills, sludge, tramp oil and waste water. Coolant sumps are easily refilled, floor spills vacuumed, or contaminated liquids transferred to filtration tanks in minutes.

CENTRIFUGE RECYCLING FOR METAL PARTS DEBURRING

These self-cleaning centrifuge systems from ALMCO Kleentec automatically separate fine particulate matter from water-based solutions and produce a clay-like waste that has no special disposal restrictions.

THE RIGHT RECIPE

A Challenging Mix of Oil and Glycol: Tubular membranes handle extremely difficult oily wastewater at this Metaldyne die casting plant.