In-Line Process Monitoring

Filter by Process Zone:

The Power of Feedback

Take a closer look some of the latest technology used in machine condition monitoring and anti-restart protection for operator safety.

Gauge for In-Process Measurement Offers Time & Cost Savings

Ideal for measuring parts in harsh metal cutting environments, the Heidenhain-Specto ST 3087 RC length gauge from Heidenhain has an IP 67 level ingress protection to measure parts directly at the grinding, cutting, or forming location, instead of removing them to quality islands or laboratories.

Spindle Vibration Monitoring, Temperature and Gravity Sensing

The Artis VM-03 vibration monitoring module from Marposs

provides alarm output for acceleration in the form of warning, soft stop or hard stop, a temperature warning and a gravity value warning with registration of alarms occurring within +5 seconds of an event occurrence.

In-Line Contour Measurement Systems

Alton Steel uses two CONTOUR CHECK EDGE 2-6 axes contour measuring systems from LAP Laser to measure their hot-rolled round and square profiles.

Radix Acquires +ADD

Radix now has a larger presence in the Toronto market, with key products and services for the specialized pharmaceutical, medical device and aerospace sectors.

Heidenhain Hurricane Recovery Hotline

They want to help assist affected companies restore lost functionality of their equipment.

Advanced Coil Processing Systems

Schnutz high-end precision levelers from Burghardt + Schmidt use special simulation software and exchangeable roll cassettes for quick and easy changeovers that produce perfect, dead-flat sheet metal flatness and optimal reduction of residual stresses.

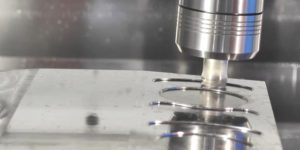

In-Machine Tool Measurement vs. Offline Presetting

In-machine laser technology is touted by machine tool builders and distributors as the way of the future and an indispensable tool for machinists. Do you really need an offline presetter if you have in-machine lasers? Yes, you do, and here’s why.

Heidenhain Names New President/Managing Director

David Doyle now has full responsibility for their operations in the U.S., Canada and Mexico.

Marposs Joins Michigan Aerospace Manufacturer’s Association

They see great growth potential for high precision measurement and inspection technologies in the aerospace and defense industries.

In-Process Grinding Gauge for Smooth Part Monitoring

The flat, compact P1dME gauge amplifier from Marposs mounts inside the operator panel of any grinding machine or as a stand-alone unit for continuous measurement that assures part production stays within tolerance and the machining cycle is optimized based on the amount of stock being removed.

New Sales & Distribution Manager at Prime Controls

Larry Jones is now responsible for general industry sales and fostering distribution partnerships.