Horizontal Machining Centers

Filter by Process Zone:

Horizontal Turning Center for Aerospace Precision

The Takisawa TS-4000YS horizontal turning center features a heavy-duty twin spindle, 12 station power turret with Y-axis, 30 hp main spindle motor and a 10 hp milling motor.

5-Axis Horizontal Machining Center for High-Efficiency Job-Shop Production

The T1 from Makino is ideal for large parts commonly machined in the energy and aerospace industries. The torque and power of the 12,000 rpm spindle make it highly productive in the machining of non-ferrous, ferrous and hard-metal materials, putting shop owners in a unique position to deliver highly competitive machining solutions for workpieces of any shape and any material.

Production Milling/Turning Large Workpieces with an HMC

The CP 8000 5-axis mill-turn center from Heller Machine Tools is ideal for machining predominantly cubic parts, particularly when the rotationally symmetric length/diameter ratio of the components is less than 1.

Hwacheon Names Nedler Vice President

Hwacheon Machinery America has appointed Robert Nedler to the position of vice president of sales.

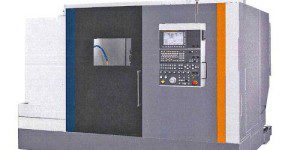

HMC Predicts and Counters Thermal Deformation

Okuma‘s MB-4000H provides a unique combination of high speed and power in a small footprint.

Horizontal Machining Center Answers Need for Higher Speed

Okuma’s MA-600HII provides nearly instantaneous access to parts, improving productivity at a high-speed axis feed of 60 m/min.

HMC Handles Large Parts in Compact Footprint

The MB-10000H from Okuma features high torque, high speed 12,000 rpm, Abso scales and NC rotary table .001 deg positioning, and Machining Navi M-i controls.

Large 5-Axis Horizontal Machining Center for Difficult Applications

Okuma‘s largest 5-axis CNC horizontal machining center has a large trunnion table with one m square pallet and has a maximum work piece weight capacity of 5,500 lb.

HMC for Machining Mid-Sized Titanium Aerospace Parts

The T2 5-Axis horizontal machining center from Makino uses a purpose-built design that provides the rigidity, dynamic stiffness, vibration damping and agility necessary for more productive titanium machining and longer tool life.

HMC Uses Precision, Power, and Torque to Boost Productivity

The bed on the HU63EX from Mitsui Seiki is a single casting supported at three points to minimize the effect of foundation fluctuations on accuracy. A thickened structure and specifically-developed rib configuration generate high rigidity.

High Precision HMC Handles Extremely Heavy Workpieces

The heavy-duty NHX4000 horizontal machining center from DMG Mori ideal for machining 24.8 in x 35.4 in workpieces that weigh up to 880 lb.

High Performance Horizontal Machining Center with Dual Pallet Changer

The servo-driven pallet changer on the EC-400 from Haas swaps each 400 mm pallet with a load capacity of 1000 lb in just 8 seconds.