Horizontal Machining Centers

Filter by Process Zone:

Highly Effective Machining of Small Aluminum Parts with 3D Contours

The a61nx-5E 5-axis horizontal machining center from Makino achieves highly productive and economical aluminum machining of small components with 3D contours.

Small Part Aerospace Manufacturing

Ideal for aluminum machining, the a51nx 400 mm high-speed horizontal machining center from Makino maximizes the average metal removal rate in both roughing and finishing applications.

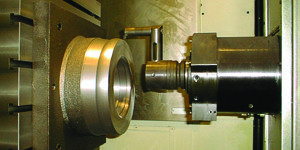

HMC Turn-Cut Function Eliminates Need for Secondary Turning

Turn-Cut processes work on Okuma MA and MB series of horizontal machining centers without the need to use secondary machinery for a turning application. In some cases, it can also be retrofitted to an existing Okuma machining center.

5-Axis HMC is Right Sized for Small Aerospace Parts

The a61nx-5E from Makino is uniquely sized for small components, featuring 3D contours without compromising the highly productive spindle performance and 5-axis capabilities of larger aerospace machines.

5-Axis HMC for Large Industrial, Energy and Aerospace Job Shop Production

The rigid design, versatile cutting capabilities and sizable work envelope make the T1 5-axis horizontal machining center from Makino an ideal fit for machining both soft and hard metals.

Smart HMC with User-Friendly Interface for Heavy Duty Machining

The intelligence system of the Tongtai HA-500II horizontal machining center from Absolute Machine Tools includes a tool management system, maintenance map, integrated monitoring of the hydraulic system and cooling system to avoid thermal fluctuation and vibration, and centralized management of the air pressure and lubrication systems.

Milling, Drilling, Tapping and Boring Brake, Engine and Transmission Parts

The compact H15 and H15B horizontal machining centers from Sugino feature BT30 high-pressure, coolant-through spindles with maximum speeds up to 15,000 rpm and 20,000 rpm, respectively.

4-Axis Machining Centers Offer Increased Energy Savings

The Heller H 4500 4-axis machining center is capable of energy savings of up to 30 percent compared to conventional machine designs.

High Speed Horizontal Machining for Faster Cycle Times

With the inclusion of a lightweight column featuring a rigid stepped X axis rail design, HMC400 from OKK USA achieves a rapid feed rate of 63 m/min (2,480 ipm) with acceleration of 1 G (XYZ).

HMC Offers High Precision with Heavy Cutting Power

The HU63EX horizontal machining center from Mitsui Seiki is engineered to boost metalworking productivity with repeatable precision performance. In turn-boring operations on 10 consecutive workpieces, the HU63EX achieves concentricity within three microns, according to the company.

Unattended Next Generation Machining Center Handles Wider Variety of Parts

The Horizontal Center Nexus 4000-III Horizontal Machining Center from Mazak is ideal for shops looking to implement horizontal machining centers as go-to workhorse machines for high-volume part processing operations.

Horizontal Machining Center for High-Efficiency Job Shop Production

The T1 from Makino is ideal for large prismatic or cylindrical parts commonly machined in industrial, energy and aerospace industries.