Horizontal Machining Centers

Filter by Process Zone:

Medical Machining: Machine Tools

Take a closer look at some of the newest equipment that can help contract manufacturers meet the machining, micro machining, and laser processing demands for smaller and more complex surgical implants, orthotic devices and medical instruments that are being made from newer materials – and still hold their costs down.

Next Generation Small Part 5-Axis Medical Machining

The a51nx-5XU 5-axis horizontal machining center from Makino enables manufacturers of complex medical parts to obtain the highest levels of utilization and efficiency.

Flexible Machining Center Configures to Wide Range of Applications

The compact Hüller Hille NBH P 80 from FFG has a choice of spindles, highly precise and dynamic rotary tables, and CNC controls that allow for flexible configuration. Its chain-type magazine has 60 locations that can be manually loaded during machine operation.

Space-Saving, Multi-Tasking HMC Reduces Cycle Times

The Mycenter-HX250iG from Kitamura Machinery uses ultra-high speed rapids for high efficiency and the ability to drill, mill, bore, tap, thread and turn light to heavy duty materials on a single machine.

Two Promotions at Matsuura Machinery USA

Shawn Buboltz is their new national service manager and Roger Breeggemann is their new service coordinator.

Efficient Five-Axis Machining Begins at the Core

The FA1050 5-Axis horizontal machining center from Toyoda Machinery provides competitive boring, end milling, finish cutting, threading and U-axis machining on difficult materials such as Hastelloy, Inconel, Nichrome and other exotic metals.

Matsuura Machinery Adds Engineers

Jonathan Sabata is their new senior applications engineer and Robert McClung is a new service engineer.

Under the Hood: Automotive Machining

New powertrain components. More sensors and electronics parts. Increasing part complexity. Difficult to cut materials. Faster delivery. How do automotive suppliers navigate to profitability through this stormy sea of lightweighting and driverless cars?

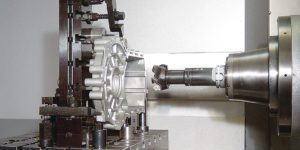

Gearmaking for Powertrains

GMTA offers a full line of Rasoma gear machines in a variety of configurations with full automation for milling, hobbing and shaping applications.

Reduce Processing Time of Large Mold Tooling, Die Cast Parts

The dual-head configuration of the EDNC21 from Makino enables shops to process multiple fine details in a part at the same time, reducing total processing time at the same level of accuracy and surface finish as sinker EDMs one-tenth its size.

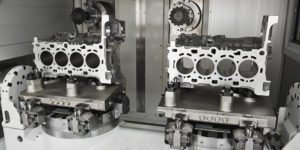

Machining Cylinder Heads, Cylinder Blocks, Gearbox Housings

The Urane 25 horizontal machining center from Comau handles the most demanding complex machining of lightweight materials, including aluminum prismatic parts.

Agile Production of Crankshafts, Cylinder Blocks

MAG offers the Boehringer 221/226 Cx that is ideal for milling, turn broaching and turning new generation crankshafts, and SPECHT horizontal machining centers with integrated honing technology for boring cyllinder blocks.