Honing Machines

Filter by Process Zone:

Affordable Power-Stroke Honing for Small Shops

Ideal for multiple-land and tandem bores, heavy/odd shaped parts, keyed or splined bores, blind bores and thin-wall parts, the value-priced SSH-1680 honing system from Sunnen brings power-stroke efficiency to small shops for sizing complex bores up to 60 mm diameter and 250 mm length.

Honing Machine Optimizes Gear Finishing

Using direct-driven, digitally controlled spindles for the tool and the workpiece, the Präwema SynchroFine 205 HS gear honing machine from GMTA can produce gear finishing quality comparable to grinding for spur and helical gears, as well as shafts.

Over a Barrel

Surface finish is the one feature of a rifle barrel that cannot be controlled in hammer forging. Now, custom rifle barrel makers are learning a trick from the makers of hammer forged barrels on how to overcome surface imperfections.

A Chip Off the Old Block

Dart masters the “peaks and valleys” of custom engine block production with an advanced American-made Sunnen SV-20 flexible honing system that uses programmable control to replicate “best” engine parameters and produce expert results with minimal operator expertise.

Smart Honing Lifts Business for Aerospace Hydraulic Pumps

This second generation machining business is using a new technology that makes a 60 millionths tolerance look generous. No kidding.

GMTA Announces a New Hire and Plans for an Open House

GMTA named Maik Schminke the manager of controls engineering and programming and announced plans for an open house.

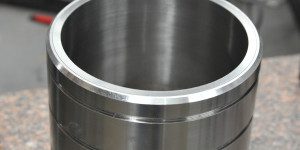

Large-Part Honing Machine for Job Shops, Repair Facilities

The SV-20 honing system from Sunnen Products is the first competitively priced large-part machine for job-shop part production with a true linear, vertical, servo-stroking system to produce precision bore geometries on compressors, oilfield components, automotive/truck blocks and similar parts.

Sunnen Honing System Offers Increased Part Capacity and Stroker Torque

Ideal for bore resurfacing, the Sunnen HTA hone is PLC controlled, handles parts up to 13.5 ft long, 21 in diameter and 8000 lbs.

Honing Machines

Honing machine tools remove stock to produce the final size and desired finish pattern on the interior of tubing or cylinder bores of almost any material by expanding, rotating and reciprocating abrasive stones of a specified grit and grade with…

Over a Barrel

The hydraulic shop of this Cat dealer salvages cylinders up to 21 ft long by re-surfacing them with an HTA tube hone, saving their customers 80 percent or more over cost of new barrel.

Perfect Holes in Hard Material – Made Easy

Exotic materials specialist Damen Carbide Tool Co. expands its holemaking capability and business base with honing capacity to 9 in diameter and a 60 in stroke length using hones from Sunnen.

Smarter Tool Feed Enhances Production Honing

This new tool feed technology from Sunnen servo-controls the force in the honing tool feed system to maintain the optimum cutting load on the honing abrasive throughout a cycle, irrespective of the incoming part’s hardness, geometry or size variation.