Grinding Machines

Filter by Process Zone:

DYNABRADE INTRODUCES NEW LINE OF ALUMINUM HOUSING POWER TOOLS

Strong housing is machined from a single piece of aluminum bar stock.

Gear Manufacturer Achieves Consistent Quality with Automated Robotic Cell

An adaptive-finishing solutions developer combined an ABB robot, Renishaw spindle probe with radio signal transmission, and a twin-pallet system into a system that machines one gear while another is loaded.

Vision System Simplifies Tool Detection and Alignment

Released by United Grinding North America and Walter Tool, a measurement system for advanced grinding/eroding machines helps manufacturers optimize production of small, high-precision parts by automatically detecting and aligning tools, blanks, and other workpieces.

Two-in-One Machine Grinds and Erodes

One of the two spindles on Vollmer’s VHybrid 360 can be used to grind and erode while the other spindle grinds. Manufacturers save time by machining solid carbide or polycrystalline diamond (PCD) drills, milling cutters, and reamers in one set-up.

Quarter-Inch Right-Angle Die Grinder

Milwaukee Tool’s cordless M12 Fuel’s brushless motor is more powerful than pneumatic-powered ¼-in right-angle die grinders.

Bevel, Face & Bore Without Cutting Fluids

Hand-held Millhog bevelers from Esco Tool feature an extra-rigid blade-locking system, blades that incorporate a radical chip breaker that transfers heat so cutting fluids aren’t necessary, and a holder that enables the blade to get under the material to pull a thick chip.

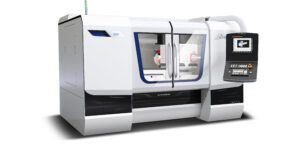

United Grinding Offers Full Range of Internal Cylindrical Grinders

A portfolio of 10 Studer machines includes several universal-type models as well as those designed for high production and for radii grinding operations. Control software enables capabilities such as in-process monitoring and the ability to string various cycle times into ISO code.

Glebar Company Announces the Acquisition of Tridex Technology

Adds electrochemical grinding (ECG) for both cutoff and precision grinding solutions.

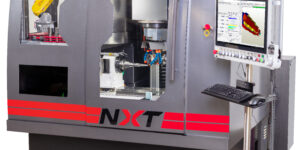

Small-Footprint Grinder with Large Work Zone

Star SU’s easily configurable NXT 5-axis grinding machine gives manufacturers the ability to run small- and large-diameter wheels to sharpen straight and spiral gash hob designs as well as disk-, shank-, and helical-type shaper cutters, Scudding cutters, and a wide range of round tools.

Increase Productivity with a Five-in-One Machine

The Elb-Schliff millGrind BL10 from Precision Surfacing Solutions (PSS): grinding, drilling, and milling in one clamping; deep grinding and, with an optional laser head, deposition welding in the other. A complete machining solution for aerospace manufacturers.

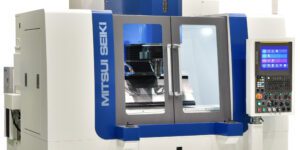

Compact Automatic Jig Grinder

Mitsui Seiki’s new-and-improved J350G grinds small- and large-diameter holes as well as multiple features using a single wheel in a continuous, automatic mode. The machine is 50% smaller than the previous model, giving manufacturers more options for shop floor usage.

Power Skiving and Gear Shaping in One Machine

A hydraulic chuck combined with a changeable back stop and slotted collet, the Mytec Hydraclamp paves the way for power skiving by enabling users to clamp different diameters and components with one hydraulic chuck.