Grinding Machines

Filter by Process Zone:

EtherCAT Remote Pendant Provides Multiple Benefits

The AMI 5000 remote pendant from ANCA Motion works with any control system that supports an EtherCAT fieldbus. In addition to enhancing shop safety by keeping operators away from machines, the pendant offers a number of customizable options.

Shine On with Two-in-One Part-Production, Re-Sharpening

United Grinding’s Walter Helitronic Raptor Diamond brings grinding and eroding technology into the shop that doesn’t need automatic tool support systems or automatic grinding wheel/electrode changers – but demands high flexibility and performance. Fine Pulse Technology produces super-fine finishes normally found in polished tools.

One Thousand Parts a Day to Help Accelerate Medical Equipment Production

TCI Precision Metals executes an all-hands-on-deck initiative to produce a high volume of precision machine-ready blanks that can reduce production time on ventilators, medical testing equipment and other essentials during the pandemic. They’re shipping 1,000 blanks a day and continue to expedite production.

Grinders Designed for Punishment

Metabo puts the Power-Up Grinders series on the market, offering higher RPM and amps than their previous models. The tools include 11 metalworking grinders for weld cleaning and removal, pipefitting, metal fabrication, shipbuilding, and beveling. Added to that are four concrete grinders built for a beating in concrete/masonry applications

Cost-Effective Tool Grinding for Re-Sharpening Sector

United Grinding focuses on the re-sharpening sector of the rotationally symmetrical tool market with its versatile Walter Helitronic Raptor. It’s the solution for shops that don’t need automatic tool support systems and automatic grinding wheel changers – but where high flexibility is required in the work area for diverse tool types.

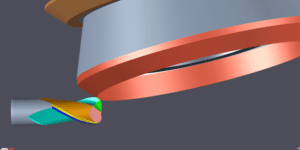

Laser Line Ultra Simplifies Micro Cutting Tool Production

United Grinding’s Laser Line Ultra uses an 8-axis configuration and picosecond lasers to machine complex micro geometries in cutting tools regardless of the material’s hardness.

CNC Gear Hobbing Machine

Helios Gear Products introduces YG Tech’s Helios Hera 150 CNC machine to North America. The easy-to-program machine provides compact vertical hobbing for gears up to 6 inches (150 mm) in diameter.

Burr-Free Cutoff Machining

Available for both electrochemical (ECG) and abrasive applications, Glebar’s Tridex CS1-E cutoff machine uses an electrochemical reaction to produce burr-free cuts on tubing from 0.012 inches to 3.15 inches in diameter.

Microgrinder for Medical Devices, Instruments

Glebar’s CAM.3 is designed for the manufacture of guidewires with flats, multiple tapers, hex shapes, and other complex geometries as well as K wires, bone pins, orthopedic and sports medicine implants, instruments, and single-use disposable products 0.005 inches to 0.375 inches in diameter.

KV Tooling Wins First Place in ANCA’s Tool of the Year Competition

Entries were judged on surface finish, specified nominal tolerance, tightest tolerance, and level of complexity.

ANCA Updates ToolRoom RN34 Software

In addition to several new tool types, the package reduces setup time from hours to 5 minutes via a new tool-balancing feature and provides an intuitive interface for creating complex endmill geometries that minimize chatter. For example, the constant-helix ballnose option is replaced by a graphical drag-and-drop designer with optimized irregular helix curves to reduce vibration and near-instant visualization by switching from 2D to 3D projection of the cutting edge.

HIRE FOR YOUR FACTORY’S FUTURE

How to develop and nurture your own innovation hub.