Grinding Machines

Filter by Process Zone:

Add the Latest Controls to Older-Model Grinding Machines

Owners who rebuild their Walter Helitronic Power machine can get the same speed, functionality, and ease of use as new models without the expense of buying a new machine with standard automation features.

Cylindrical Grinders For Precise Packaging Components

United Grinding’s Studer S41 (universal) and S131R (radius internal) are designed to produce large, heavy canning and die-forming components from the extremely hard metals commonly used in the packaging industry.

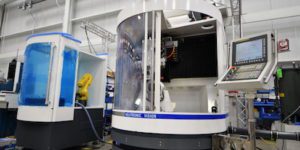

Updated 5-Axis Tool Grinder

Star Cutter’s NXT runs the latest NUM tool-grinding software, provides automated marking, accommodates denser pallet arrays, and produces multiple profiles for tools up to 10 inches in diameter in a single run.

Heavy-Duty Bench Grinders

Palmgren claims its line of heavy-duty bench grinders provides four to seven times longer duty cycle under load and eight times less speed degradation than competing products. Wheel diameters: 6 to 12 inches.

Thread Grinder Produces Workpieces More Than 6 Feet Long

Automatic phase, notch-position and effective-diameter adjusters along with automatic wheel in-feed position adjustment ensure Mitsui Seiki’s GSH 200A thread grinder delivers consistently repeatable precision.

High-Speed, High-Precision Surface Grinder

Featuring a longitudinal feed rate of 975 inches/minute and vertical feed of 17 inches/minute, Kaast’s F-Grind AH Series is equally capable of achieving a high-quality surface finish or critical dimensions on cutting and threading tools, punches and gauges.

Form Grinding Ball Valves Raises Output and Reduces Cost

Glebar’s PG-9DHD centerless form grinder accepts a 10-inch-wide work wheel to produce multiple parts per cycle in a single infeed motion. It shapes spherical and cylindrical components 0.050 to 4 inches in diameter.

Perform Two Gear-Machining Processes in One Clamping

Both a grinding and a turning machine, EMAG’s VLC 350 GT speeds transmission component production by enabling multiple machining processes of chucked parts in a single clamping operation.

Rotary Table Surface Grinder Cuts Replacement Tooling Costs Almost in Half

Get more life out of virtually any brand of tooling for turret presses, ironworkers, and rooftop punches as well as progressive and other dies with DCM Tech’s turnkey punch and die grinder (PDG) with 18-inch rotary table.

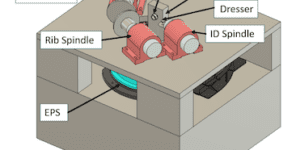

Grinding Method Eliminates Need for Multiple Machine Tools

Almost any operation that requires a combination of high accuracy and high force can be improved with the Eccentric Positioning System (EPS) from Coventry Associates. The grinder uses three circular rotary tables on top of each other instead of linear slide systems.

Creep Feed Grinder Makes Light Work of Large, Heavy Components

United Grinding’s Blohm Profimat XT relies on a 80 hp spindle and 20-inch-diameter grinding wheels to fashion workpieces weighing almost 1,800 pounds. Control interface customized to visualize machine monitoring data.

Versatile Machine Handles Traditional Gears to Chucked Components with Internal Taper

Both a grinding and a turning machine, EMAG’s VLC 350 GT speeds transmission component production by enabling multiple machining processes of chucked parts in a single clamping operation. The flexible machine handles diameters up to 14 inches.