Grinding Machines

Filter by Process Zone:

Powerful Next Generation Vertical Grinders for Oil and Gas Applications

CP3330 and CP3340 series industrial vertical grinders from Chicago Pneumatic can remove material twice as fast when contouring, deburring, cutting, finishing and weld cleaning cast iron, steel, stainless steel, aluminum, composite, magnesium and titanium.

Grinders for Difficult Applications in Limited Space on Oil and Gas Platforms

Lightweight FA-20 series 2 in angle grinders and die grinders from Fuji Air Tools feature a distinctive low profile grinding head design that is particularly suited to metal grinding for mold maintenance, weld bead removal, deburring and chamfering on oil and gas platforms and in other metalworking applications.

How to Increase Material Removal Efficiency and Your Bottom Line

From foundries to fabrication shops and final finishing, all areas of metalworking are looking to increase profitability through process efficiencies. Pneumatic tools that are appropriate for material removal can enable users to improve their productivity significantly. Here is a review of the latest air tools and how they are best suited to particular applications, along with considerations to take when specifying tools.

Air-Powered Abrasive Belt Machine with American Flag Design

The Dynafile abrasive belt machine from Dynabrade is ideal for light corner weld removal, blending of welds, grinding, deburring, blending and finishing normally inaccessible areas on metal, plastic, fiberglass and other composites.

Milwaukee Tool Expands in Three Mississippi Locations

They are investing $33.4 million and creating 660 jobs at their sites in Greenwood, Jackson and Olive Branch.

High Precision Internal Diameter Grinding of Powertrain Components and More

The Landis-Bryant UL2 multi-surface grinder from Fives Landis is ideal for high speed, high precision grinding of bores, faces and contours of bearing rings, valve lifters, gears, universal joint cups and CVJ components, and especially suitable for machining parts with an external diameter up to 177 mm.

Fewer Pieces, More Business, All Fast

The flexibility, accuracy and speed of universal cylindrical grinding built this job shop a reputation for fast deliveries, superior part finishes and versatile machining of high quality prototypes and critical automotive and trucking parts, and quick turnarounds of fixtures to reverse engineer worn/broken parts.

Starrag and Walter Team Up on Turbine Production

They join together to focusing on how digitalization can make turbine manufacturing more productive and reliable.

United Grinding North America Opens New Headquarters

Their new 110,000 sq ft building consolidates diverse product lines and customer service operations for higher productivity and faster response times.

Lapmaster Wolters Becomes Precision Surfacing Solutions

The new brand identity reflects their transformation as a technology-driven company into a diversified industrial group.

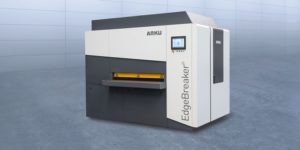

Deburring, Edge-Rounding and Leveling Systems Reduce Operating Costs Downstream

The EdgeBreaker 4000 Plus from ARKU removes burrs/slag to create a clean, even surface and sides on parts up to 3.3 in thick. Their FlatMaster 55 precision leveler quickly delivers leveled and stress-relieved parts and sheets that have been punched or cut by laser, flame and oxyfuel.

Quality Means Getting the Right CNC Centerless Grinder

With the flexibility to run a variety of parts and two or three different parts and materials per day, a new-to-market centerless grinder helped this Midwestern manufacturer obtain AS 9100C certification and meet the quality requirements of their customers in the aerospace and defense industries.