Grinding Machines

Filter by Process Zone:

Pneumatic Right Angle Grinders for Demanding Fabrication Jobs

For demanding fabrication work in foundries, shipyards, machine shops and rail car manufacturing, pneumatic Right Angle Grinders from Cleco are designed for rigorous use and long life.

Powerful Grinders and Sanders for High Volume Fabrication Jobs

The CP3550 series of power tools from Chicago Pneumatic combine high power with industrial durability for high volume grinding, chamfering, weld preparation and cleaning, cutting, finishing and sanding, as well as MRO applications.

Precision Gear Grinding of Long Shafts

Ideal for aerospace suppliers and job shops, the travel of the main and counter column in the compact LGG 400 M gear grinding machine from Liebherr has been extended for precision machining of long shafts.

Higher Precison Universal Grinding Systems

With an adjustable wheelhead for straight and angled configurations, the GL4i-50 Switch universal grinding machine from JTEKT Toyoda can perform precision grinding of large parts as well as smaller diameter journals.

Next Generation Continuous Dress Creep Feed Grinding

The heavy duty Blohm Profimat XT continuous dress creep feed grinder from United Grinding combines exceptional rigidity and power with fast axis speeds for exceptional grinding productivity in machining large parts with high stock-removal requirements.

Automated Double-Side Fine Grinding

Using a Twin Loader for automated machine tending, the highly rigid, high precision Peter Wolters AC microLine 1250-F/H from Lapmaster Wolters combines servo-drive technology with in-process load pressure to guarantee high stock removal rates with high precision contactless measurement control.

Whittemore Partners with NSK America

They now represent and sell NSK high-speed precision machine tool spindles and hand tools in Illinois and Wisconsin.

United Grinding Names Ellison Technologies as Distributor

Ellison will be their exclusive sales and service source for grinding systems in Texas and Louisiana.

Flexible Robotic Precision Finishing Systems

Robotic finishing systems from Fastems eliminate variations that are common in hand-finishing operations, maximize the output of consistently precise parts, and relieve employees of tedious and tiring hand finishing activities.

Doing Tasks with Robots That Were Not Possible Before

The intuitive Force Guide integrated force control system from Epson Robots enables robots to perform grinding, polishing, part insertion, screw driving and other high precision operations that require high performance motion guidance.

How to Give Robotic Grinding and Polishing Processes a Sense of Touch

Ideal for robotic assembly, grinding, and polishing operations, the Axia80 F/T sensor from ATI obtains feedback from force and torque loads as a process is occurring to make robotic and automated processes more acute and responsive.

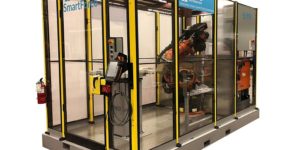

Robotic Grinding, Deburring and Polishing Cell

The SmartForce robotic cell from ABCO Automation uses human-touch capabilities to grind, deburr, or polish in any orientation, even over contours, with consistent, quality results that remove employees from working in manual machining processes under gritty, taxing, and hazardous conditions.