Gear Cutting Machines

Filter by Process Zone:

Flexible Gear Cutting and Worm Milling for Medical Devices

The compact AF110 gear hobbing center from Affolter Technologies has improved rigidity that guarantees short cycle times and highest efficiency.

IMTS 2016: Gear Generation

Take a closer look at gear cutting, forming and finishing, as well as broaching, shaping and slotting machines for traditional auto, construction, mining and ship-building applications, plus the emerging alternative energy and wind power sectors. You’ll find advancements in abrasive machining to improve dressable tooling applications and increased multi-functional, automated solutions to minimize workpiece movements to improve overall production time.

Advanced Gear Generation Technologies

The family of vertical pick-up lathes, advanced crankshaft grinding, multiple spindle turn/grind machines, electro-chemical and laser welding technologies, and heat treatment from EMAG can be integrated into work cell arrangements for automotive, off-highway and other power transmission component manufacturing.

Fast and Flexible Automated Gear Grinding

The RZ260 gear grinding machine from Reishauer is ideal for handling higher loads and forces that occur when grinding larger gears.

NUM and Feng Chia Develop Intelligent CNC Gear Hobbing

Developed under Industry 4.0 planning and design, intelligent gear hobbing expands traditional process capabilities through use of a CNC-PC communication framework.

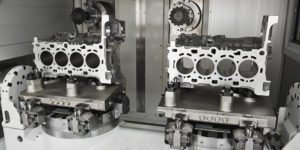

Under the Hood: Automotive Machining

New powertrain components. More sensors and electronics parts. Increasing part complexity. Difficult to cut materials. Faster delivery. How do automotive suppliers navigate to profitability through this stormy sea of lightweighting and driverless cars?

Gearmaking for Powertrains

GMTA offers a full line of Rasoma gear machines in a variety of configurations with full automation for milling, hobbing and shaping applications.

Steering Pinions for Driverless Cars

This modular production line for steering pinions from EMAG turns the raw parts, cuts the teeth, and hardens and finishes tooth profiles.

Gear Motions Names New Vice President

Paul Andruszko now directs their Buffalo operations, including the Oliver/Pro-Gear and Niagara Gear divisions.

IMTS 2014: Gear Generation

Take a closer look at gear cutting, forming and finishing, as well as broaching, shaping and slotting machines for traditional auto, construction, mining and ship-building applications, plus the emerging alternative energy and wind power sectors. You’ll find advancements in abrasive machining to improve dressable tooling applications and increased multi-functional, automated solutions to minimize workpiece movements to improve overall production time.

ITAMCO Engineer Wins Prize for Google Glass Application

Joel Neidig has been awarded a $75,000 prize for his research project titled “Expanding Manufacturing’s Vision: MTConnect® and Google Glass.”

GMTA Executive Wins Next Generation Award

Scott Knoy received the presitgious achievement award from the American Gear Manufacturers Association at their annual meeting in St. Petersburg, FL.