Gear Cutting Machines

Filter by Process Zone:

Compumachine Partners with Heller Machine Tools

Compumachine is now the exclusive dealer in New England for sales, service and support of Heller equipment.

Highly Productive Cutting of Small Gears for Medical Equipment

The Affolter AF110 plus gear hobbing center from Rotec Tools maximizes productivity in cutting small spur, helical, frontal, bevel, and crown gears for medical equipment, with cutter-spindle speeds up to 12,000 rpm.

Heller Machine Tools Increases Sales Force

Peter Stackpoole, Steve Gugan, Marc St-Pierre, and Dave Mondek have joined their sales team.

Gear Motions Appoints Two Executives

Dan Bartelli is now the director of operations for their Nixon Gear Division and Anna Pastore is their new corporate controller.

Koepfer America Updates Helios Gear Brand

They now carry a full range of Helios gear manufacturing systems, machines and tools for gear manufacturers.

Bourn & Koch Expands Distributor Network

Five new distributors will help increase their sales and support across the Midwest, West, Northwest U.S. and Alberta, Canada.

Turnkey Gear Skiving Systems and Modular Automated Pallet Handling

The skiving3 process for internal gearing with medium size and quantity using LK series machines from Liebherr is much faster than shaping and more economical than broaching.

How Hard Scudding is Shaping New Horizons

This process development is a viable and very cost-effective alternative to conventional grind-and-hone operations for automotive powertrains and other gear market segments, yielding a highly attractive cost per piece, extended tool life scenario, reduced capital outlay and more consistent end product bode.

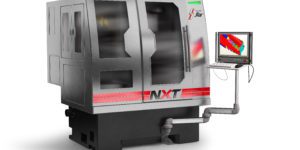

Next Generation Tool Grinding and Advanced Gear Hobbing

The compact NXT CNC 5-axis tool grinder and the FFG Werke Modul H 80-200 vertical gear hobbing machine from Star SU are suited for automotive as well as job shop applications.

Forest City Gear Hires New Managers

Erik J. Spurling is now their director of sales and John Young is their quality assurance manager.

DVS Focuses on Automation

They acquire automation supplier rbc robotics, which specializes in camera-guided robot systems for machine tools.

Flexible Next Generation Gear Hobbing

The LC 280 α gear hobbing machine from Liebherr offers shops the unique opportunity to machine gears and shafts with a workpiece diameter up to 280 mm and a shaft length up to 500 mm, the range of the most typical machining sizes required for a gear.