Drilling Machines

Filter by Process Zone:

High Speed Machining Unlocks Huge Productivity for Brass

A new study reveals how U.S. machine shops can ramp up production speeds on brass parts with no loss of workpiece quality or tool life.

How Smart Drilling Improves Bone Fracture Operations

When repairing a fracture in osteosynthesis, doctors once had to manually determine bone diameter and hole depth during the operation using a gauge, which could lead to mistakes in screw selection. Now an intelligent drilling machine can properly measure the length of screws without error.

How a Pneumatic Tapping Arm Eliminates Mental and Physical Fatigue

This fabrication shop specializes in residential work and custom one-off designs that require joining dissimilar materials and demand a lot of elbow grease and mental concentration. These jobs took a toll on workers, causing fatigue that led to rework and scrap – until they discovered a pneumatic tapping arm.

Portable Morse Taper Magnetic Drill Can Tackle More Job Operations

The HMD2MT portable magnetic drill from Hougen features a #2 Morse Taper arbor system for increased versatility, giving steel fabricators the flexibility to tackle more job operations with one tool.

FlexArm Breaks Ground on New Facility

Their new $4 million state-of-the-art headquarters will house R&D, engineering, customer testing/runoff, manufacturing, and administration.

Mitsui Seiki Marks Milestone

They celebrate their 90th anniversary this fall.

New Director of Financial Services at Methods Machine Tools

Matthew Sheehan will help expand their finance program and tailor competitive finance products.

Coldwater Adds Jig Bore to Machining Operations

Their Mitsui Seiki J6CNC achieves ±.00004 in positioning accuracies for machining automotive, aerospace, electronics, semi-conductor and machine tool parts.

Tackle More Steel Fabrication Jobs with One Tool

Powered by a two-speed motor with a forward/reverse option for use when tapping holes, the HMD2MT portable magnetic drill from Hougen features a #2 Morse Taper arbor system for increased versatility.

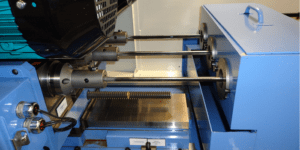

What is Possible with Deep Hole Drilling?

Deep hole gundrilling, BTA drilling, bottle boring and skiving/roller burnishing machines from UNISIG can make components for medical, aerospace, die and mold, automotive, oil and gas, energy, firearms and hydraulic cylinder applications, as well as the tools used to produce those components.

High Volume Gundrilling of Scroll Compressor Drive Shafts

The DeHoff 518 Cell from Kays Engineering uses nine gundrilling spindles to drill opposing holes in balanced throughput: three on a single machine base for the larger diameter shorter hole, and six others on two separate machine bases for the smaller diameter deeper hole.

Magnetic Drilling Units Deliver More Power, Versatility and Mobility on the Jobsite

Newly redesigned ICECUT 100 and 200 mag drills from Walter Surface Technologies guarantee productive drilling with almost no risk of motor overloading, overheating, or premature cutter breakage.