Drilling Machines

Filter by Process Zone:

Global Gundrilling OEM Celebrates 40 Years of Growth

Kays Engineering Inc., which makes the DeHoff, Eldorado, and TechniDrill brands of gundrilling machines, has grown from small welding and repair shop to a 60-employee leader serving customers in 30 countries across five continents.

Turnkey Deep Hole Drilling Solutions

Why buy a new machine when you can convert an existing piece of equipment for much less money? Somex MAX spindles and accessories can be added to transfer machines, special-purpose machines, and turning machines to perform deep hole drilling.

Portable Magnetic Drill Adds Multiple Features

With its powerful performance, lightweight size, small footprint, and hole capacity, the HMD904 is the most popular model in Hougen Manufacturing’s line of magnetic drills. Upgrade improve safety and lower maintenance requirements.

Cutting Tool Manufacturers Find Opportunity in Billion-Dollar Deep Hole Drilling Market

Understanding the application and being aware of common challenges can help make a difficult operation both productive and profitable. An ANCA product manager explains the different types of cutting tools for deep hole drilling and how to overcome common challenges.

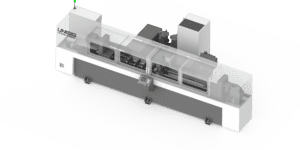

Automation-Ready Gundrilling Machines

Offering operational flexibility, improved performance, and effortless operation, UNISIG’s next-generation UNE Series deep-hole drilling systems are equally effective in high-volume/low-mix and low-volume/high-mix production environments.

Need Small-Diameter Deep Holes? Here’s Your Micro Drill

Walter delivers high precision and productivity with the Supreme DB133, a solid carbide micro drill that prolongs tool life in steel, cast iron and nonferrous materials. They’re available in diameter range from 1/32-5/64 in. and 0.5 to 2.95 mm

Cost-Cutting Gundrills for Medical Device, Instrument Deep Hole Drilling

Star SU’s single-flute solid-carbide gundrills are engineered and manufactured to meet part print requirements when working with the complete range of titanium and stainless steel materials.

Railroad Industry Uses Kays Engineering Boring Technology

Custom DeHoff 3060 boring machine features Beckhoff CNC controls and 40-horsepower spindle motor with 4-speed gearbox to meet rigorous material-removal requirements. Workpiece loading and fixturing can also be customized.

EtherCAT Remote Pendant Provides Multiple Benefits

The AMI 5000 remote pendant from ANCA Motion works with any control system that supports an EtherCAT fieldbus. In addition to enhancing shop safety by keeping operators away from machines, the pendant offers a number of customizable options.

Mold Makers: Universal Spindle Streamlines Milling, Gundrilling

Unisig built the USC-2M and USC-3M for tough applications – both can handle all types of milling and gundrilling metal. And their universal spindle helps users reduce changeover times when switching between those two operations.

Boring Technology for Automotive Engine Rebuilding

Kays Engineering’s 3-axis DeHoff 1036 is designed for re-boring the CAM journals of automotive engine blocks. The single-spindle CNC boring machine has a capacity of 1 in (25.4 mm) and depth of 36 in (914 mm).

KV Tooling Wins First Place in ANCA’s Tool of the Year Competition

Entries were judged on surface finish, specified nominal tolerance, tightest tolerance, and level of complexity.