Deburring Machines

Filter by Process Zone:

Three Ways to Optimize the Automated Brush Deburring Process

Want to reduce costs, improve process consistency, simplify part assembly, increase edge strength and create a more uniform finish? A wide range of operations are good candidates for a switch to automated deburring, and following these steps can help optimize the process for efficiency, quality and productivity.

How to Put Seeming Waste to Good Use

Coal-fired power plants are turning to ash removal conveyors that eliminate the need and use of ash ponds and support EPA regulations on the safe disposal of coal ash in landfills and surface impoundments. This job shop fabricated five of these large, sophisticated submerged scrapper conveyor systems, which one power plant now uses to recycle coal ash, conserve natural resources and save energy.

Lapmaster Wolters Becomes Precision Surfacing Solutions

The new brand identity reflects their transformation as a technology-driven company into a diversified industrial group.

ISO Finishing Plans to Double in Size

They will add 10,000 sq ft for equipment and services for the medical, firearm, automotive, additive manufacturing and aerospace industries.

United Performance Metals Installs New Equipment

They add a 6 kW fiber laser, deburring and leveling machinery to their production operations.

Laguna Tools Acquires SuperMax Tools

This deal adds some best-in-class brush and drum sanders to their product lines.

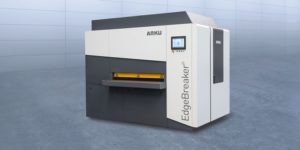

Deburring, Edge-Rounding and Leveling Systems Reduce Operating Costs Downstream

The EdgeBreaker 4000 Plus from ARKU removes burrs/slag to create a clean, even surface and sides on parts up to 3.3 in thick. Their FlatMaster 55 precision leveler quickly delivers leveled and stress-relieved parts and sheets that have been punched or cut by laser, flame and oxyfuel.

Deslag Line for Metal Service Centers

The Deslag Line from LISSMAC uses Power Pin Belts on top and bottom that chip away the slag formed from plasma or oxy-fuel cutting systems, then two grinding belts on the top and bottom complete a final grind of any slag left on the part, and two sand block belts on the top and bottom round the edges on the part.

Uniform Two-Sided Deburring, Buffing and Polishing of Parts

The TB 1600 64 in top / bottom machine from Apex Machine Group processes both the top and bottom surfaces of each part in a single pass with 100 percent uniformity.

U.S. Machine Tool Orders Accelerate

June manufacturing technology orders climbed 6.5 percent over May to $373.2 million.

ISO Finishing Becomes U.S. Distributor for BV Products

They now provide BV vibratory surface finishing systems to job shops across the U.S.

Abtex Hires New Design Engineer

Josh Prescott provides customer support and helps to direct equipment designs.