Cutting Tools

Filter by Process Zone:

LMT Fette’s Precision Tools Bring Ideas to Life Using ANCA’s iGrind Software

As a leader in gear cutting and rolling tools, LMT Fette matches machine and software performance with production goals with its ANCA machines.

How Advances in Aluminum Component Machining Support the Shift to EVs

Commentary from Sandvik Coromant notes how selecting tools made from advanced materials better assists in machining aluminum.

Tooling and Workholding Solutions Offer Versatility and Reductions in Costs

Handle the toughest applications and cut down on the number of changes thanks to advances in tool life.

Walter’s Face, Shoulder and Slot Drill Milling Cutters Reduce Cutting Forces

Walter introduces new suite of products for machining aluminum, Al-Si alloys, magnesium and magnesium alloys.

Tool Alliance Celebrates 50 Years in Business

Cutting tool manufacturer has built an enviable reputation for the quality and durability of its solid carbide and indexable carbide cutting tools.

Reduce Tooling Inventory Costs with Versatile Seco Milling Cutters

Square shoulder and helical milling cutters provide high material removal rates.

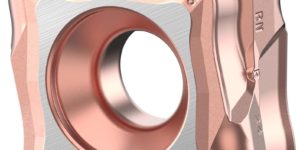

CERATIZIT’s New Insert Grades Optimize Steel Turning

Three new standard coated-carbide ISO-P steel insert grades provide up to 20 percent longer tool life when compared to previous generation grades.

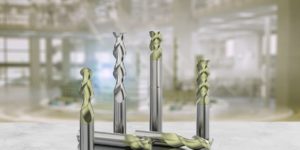

New and Improved Solutions from Niagara Cutter for Aluminum Machining

The new and improved A245/345 tooling solutions have been redesigned to reduce power consumption and improve chip evacuation in aluminum machining applications.

Walter USA’s New Tiger·tec® Gold Inserts Handle Tough Steel Turning Applications

Tiger·tec Gold for steel is the next generation of CVD coating technology for increased tool life.

Superior Products Extend the Lifespan of Tools

Long tool life is a critical component toward ensuring your shop remains competitive.

Best Practices for Reducing Consumable Costs and Extending Tool Life

Monitor and evaluate tool life to remain competitive and reduce waste.

Kennametal’s FIX8™ for Heavy-Duty Turning Features Eight Cutting Edges per Insert

The new system from Kennametal delivers the highest possible metal removal rates in turning operations with the lowest cost per cutting edge.