Computerized Maintenance Management Systems

Filter by Process Zone:

Automation Apps Increase Reliability in Smart Factory Production

Individually configurable software application packages from Liebherr can increase the control and reliability of robotic production in an Industry 4.0 operating environment.

Augmented Reality Delivers Digital Work Instructions to Field Service Technicians

Using Onsight Flow paperless work instructions from Librestream on their wearables for hands-free operation or on their smartphones and tablets, the digital field service worker can remotely inspect and troubleshoot assets quicker, safer and more consistently.

Intelligent Systems for Process Optimization

SmartMONITOR for manufacturing and AndonSPEED for the warehouse are process optimization systems from WERMA that reduce disruptions and downtime during operations.

Advanced Robots, Turnkey Workcells, Collaborative Technology and More to Increase Productivity

The heavy duty, large reach MH900 Robot; the light 6-axis MotoMini for tabletop, floor, ceiling or wall-mount installations; and the Motoman AR1440 arc welding robot are some of the latest automation systems from Yaskawa Motoman that improve productivity in a wide variety of manufacturing operations.

Universal Decoder Connects and Collects Real-Time Shop Floor CNC Machine Data

The Excellerant API universal decoder from WireFreeCNC provides small to large shops with the ability to connect every CNC machine tool controller, no matter the brand, so they can monitor and manage each machine’s data in real-time and send that data to their MES and/or ERP systems.

Moving Machine Builders and Users Toward the Digital Factory

The Mindsphere IoT operating system from Siemens is an open, customized platform for recording and analyzing large volumes of real-time, plant-wide production data used to operate, manage, program and maintain machine tools on the shop floor.

The Next Generation of Data-Driven Manufacturing Software

Merlin Tempus Enterprise Edition from Memex expands machine monitoring and management functionality with real-time data collection capabilities that capture machine-generated information and real-time sensor data, including alarm states, feed and speed rate overrides and other green-light metrics.

Analytics Technology for After-Sales Service of Equipment in Real-Time

Using Remote Service from MachineMetrics, service managers and technicians can remotely monitor, manage, diagnose and resolve a customer’s machine issues for any piece of connected equipment in the field in real-time, without the necessity of an on-site visit.

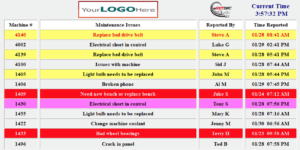

Full Real-Time Visibility of all Facility and Machine Maintenance Needs

Using eNETMD real-time Maintenance Dashboards from eNETDNC, a shop can schedule or prioritize today’s maintenance needs or even weekly, monthly and yearly preventative maintenance projects. It also offers an email server with automated notifications to improve communication within the maintenance department.

A World Without Downtime

How close are we to a downtime free age?

Don’t Play with Fire: Preventative Maintenance on Roll Formers Saves Money and Time

If you run your roll former 24/7 without maintenance, you’re playing with fire. Every maintenance program is a little bit different, but this general outline is useful for any metal roll forming machine. It includes some points of emphasis to consider, and some things that may get overlooked.

Predicting the Future of Smart Factory Maintenance

Industry 4.0 technologies, particularly given their recent price drops, are already shaping up 2018 to be the year where VR, AI and other new and exciting technologies make their way onto the plant floor.