Collets

Filter by Process Zone:

Advanced Tooling for Demanding Part Machining

New milling chucks and other toolholding innovations from REGO-FIX Tool showcase advanced tooling systems that bring precision, strength and ease of use to demanding part machining applications.

Collet Pad Jaws Maximize Productivity for Small Diameter Parts

A collet pad top jaw system from Dillon Manufacturing increases a chuck’s range of workholding capabilities, allowing more varied part geometries to be machined more aggressively with the same jaw system for shorter cycle times and more consistent quality output.

Collets

A subcategory of chucks, collets incorporate a tapered outer sleeve and an inner cylindrical surface that fits around a tool or workpiece. Collets are typically divided into woodworking and metalworking uses. In woodworking, collets are often used to hold cutting…

To Have Is To Hold

An examination of some of the latest chucks, jaws, collets and other tool and workholding technologies that can help you reduce setup time, increase spindle utilization and improve your competitive edge.

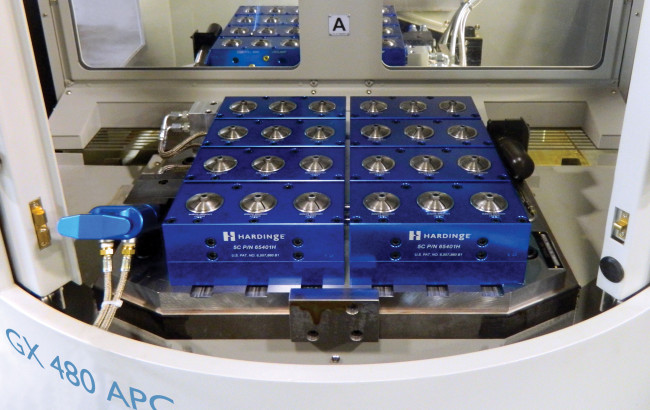

S-Pads Replace Collets in Multi-Spindle Shops

S-pads from Hardinge are much faster to change than collets from job-to-job and can be shared between many brands of machines, whether the master collet is mounted directly in a machine spindle (single or multiple), in a collet adaptation chuck, or in a collet block.

Micro Collet System for Medical Manufacturing

This system from IBAG North America delivers accuracies of one micron TIR at the collet nose and handles up to 1/8 in tool diameter to meet the precision milling and ultra small drilling demands of ultra precision parts manufacturing.